Home > Crane Parts > Container gantry crane

Container gantry crane

Lifting capacity: Typically 40–65 tons (capable of lifting 20–40-foot containers, including loaded containers), with some large models exceeding 100 tons, suitable for ultra-large containers. Span and lifting height: Spans range from 18-50m (larger for track-mounted models), with lifting heights of 12-30m, enabling multi-tier stacking (typically 4-8 layers) to enhance yard utilization. Work class: Most are A6-A8 class, capable of handling high-frequency continuous operations (average of over 16 hours per day), meeting the “24/7” operational requirements of ports. Operating speed: Lifting speed 8-30 m/min, trolley travel speed 20-50 m/min, crane travel speed (tire-mounted 10-20 km/h, rail-mounted 30-50 m/min), efficiently matching container turnover efficiency.

Specialized and efficient: Equipped with telescopic container-specific lifting equipment (capable of automatic container alignment and rotation), with a short single-cycle operation time (30–60 seconds per container), significantly improving loading and unloading efficiency. High Space Utilization: Through multi-layer stacking design, the storage density of containers in the yard can be increased by 3-5 times, saving land resources. Automation Compatibility: Modern models support semi-automatic/fully automatic operation, integrated with GPS positioning, laser ranging, and anti-sway systems, enabling unmanned operations, reducing labor costs, and improving accuracy.

Description

A container gantry crane is a large lifting device designed specifically for container loading, unloading, stacking, and short-distance transfer. With its efficient and professional performance, it has become the core equipment in ports, container yards, logistics parks, and other locations.

Tire-mounted container gantry cranes (RTG) use tires as their traveling components, eliminating the need for tracks and offering high flexibility, enabling efficient maneuvering in medium to small-sized yards; Rail-mounted container gantry cranes (RMG) operate along fixed tracks, offering outstanding load-bearing capacity and large spans, making them suitable for large-scale operations in specialized yards; Shore-based container gantry cranes are installed along the port shoreline, with an operational range covering the ship's side and the yard, serving as the key equipment for transferring containers between ships and land. Structurally, it consists of a gantry frame, trolley running mechanism, crane running mechanism, and electrical control system. The gantry frame includes a main beam and legs, with the main beam typically constructed using a box-type welded structure, and the legs designed in A-type or H-type configurations to ensure rigidity and stability during large-span operations. The trolley running mechanism is equipped with a telescopic container-specific lifting device, capable of automatically aligning and rotating containers, enabling precise handling of 20-40-foot containers. In terms of performance, the container gantry crane excels. Its lifting capacity typically ranges from 40 to 100 tons, with some large models exceeding 100 tons, easily handling heavy container operations. The span ranges from 18 to 50 meters, with a lifting height of 12 to 30 meters, enabling 4 to 8 layers of stacking, significantly improving yard utilization rates, which are 3 to 5 times higher than traditional stacking methods. The work class is typically A6-A8, capable of meeting high-frequency continuous operation requirements, with an average daily operating time of over 16 hours. The lifting speed ranges from 8-30 m/min, the trolley running speed from 20-50 m/min, and the single operation cycle time is only 30-60 seconds per container, achieving extremely high operational efficiency.

With technological advances, modern container gantry cranes also support semi-automatic or fully automatic operation, integrating GPS positioning, laser ranging, anti-sway systems, and other features to enable unmanned operation. This not only reduces labor costs but also improves operational accuracy.

Container gantry cranes, with their specialized design and high-performance capabilities, provide robust support for container handling in ports, logistics parks, and other similar settings, making them an indispensable piece of equipment in the modern logistics industry.

Features

Tire-type (RTG): No track constraints, tires use wide-base engineering tires (diameter ≥ 1.8 m), can move freely on compacted ground, minimum turning radius 8-12 m, suitable for small and medium-sized yards and multi-area dispatch scenarios, supports 90° turning on the spot, and flexibly adapts to complex yard layouts.

Rail-mounted (RMG): Operates along parallel tracks, with a larger span (30-50m) and stronger load capacity (up to 120t). It can achieve a running accuracy of ±5mm, making it suitable for large-scale operations in specialized yards. It can be efficiently dispatched through multi-machine coordination to achieve “one track, multiple machines.”

Shore-based model: Lifting height of over 30m, boom reach covering from the ship's side to the yard, equipped with an anti-sway system (sway amplitude ≤3°), capable of directly connecting to the ship's hatch, enabling seamless “ship-to-yard” transfer, with wind resistance up to level 12 (equipped with wind anchoring devices).

Intelligent control system: Integrates GPS positioning, laser ranging, visual recognition, and other technologies, supporting semi-automatic (remote control) or fully automatic (unattended) modes. Fully automatic models can simulate workflows through a digital twin system, autonomously planning paths, avoiding obstacles, and scheduling, with positioning accuracy of ±20 mm.

Multiple safety features: Standard overload protection (accuracy ±3%), travel limit (dual mechanical and electronic protection), anti-sway control, and large vehicle collision prevention (distance warning + automatic deceleration) system. Tire-type models are also equipped with tire pressure monitoring and automatic fire extinguishing devices, meeting international safety standards (such as ISO 10474).

Maintenance convenience: Key components (such as lifting devices and motors) are equipped with status monitoring sensors that transmit data in real time via an IoT platform to enable fault warning. Structural components such as main beams and legs are coated with a long-lasting anti-corrosion coating (lifespan ≥ 15 years) to reduce maintenance frequency.

Container gantry cranes combine the advantages of “specialized structure + efficient operation + scenario segmentation + intelligent upgrading” to become the core hub in the container logistics chain's “unloading - storage - distribution” process. Their performance directly determines the turnover efficiency of ports and yards, making them indispensable key equipment in modern international trade.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Span | 6-10m | 8-12m | 10-14m | 12-16m | 14-20m | 16-24m | 18-28m | |

| Lifting height | 4-6m | 5-7m | 6-8m | 6-9m | 8-12m | 10-14m | 10-16m | |

| Work Duty | A3 | A3-A4 | A4 | A4-A5 | A5 | |||

| Lifting speed | 8-12m | 6-10m | 5-8m | 4-6m | ||||

| Hoist Traveling Speed | 15-25m | 20-30m | 25-35m | |||||

| Crane Traveling Sprrd | 10-15(轮胎式)/20-30(轨道式) | 8-12(轮胎式)/15-25(轨道式) | 5-10(轮胎式)/10-20(轨道式) | 3-8(轮胎式)/8-15(轨道式) | ||||

| Rail | 轮胎式(万向轮)/轨道式 | 轮胎式(工程胎)/轨道式 | 轮胎式(宽基胎)/轨道式 | |||||

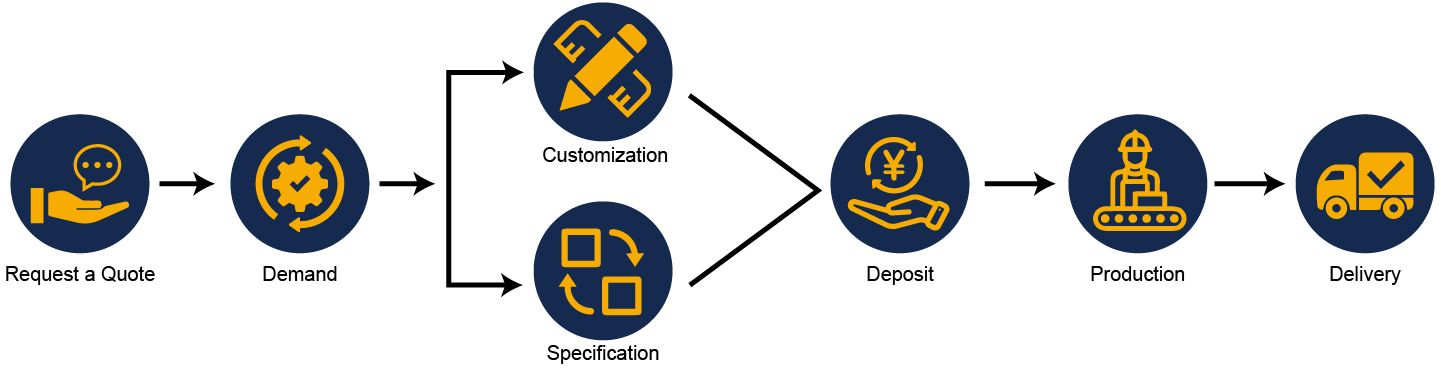

Purchasing process