Home > Products > Port Crane > Ship To Shore Container Crane

Ship To Shore Container Crane

Ship-to-Shore (STS) container cranes are critical equipment in modern port operations, designed to efficiently load and unload containers from ships to the shore and vice versa. These cranes are a key component of container terminals, enabling the rapid movement of goods and ensuring the smooth operation of global supply chains.

In the modern port environment, reliability and productivity are the key parameters. Ship to shore container cranes (STS) achieve up to 99.5% availability during actual vessel operation.

Description

Ship-to-Shore (STS) Cranes are large dockside gantry cranes found at container terminals for loading and unloading intermodal containers. Generally classified by their lifting capacity and the size of the container ships they deal with, additional parameters indicate traveling and lifting speeds, the faster the better to minimize “deadtime” and be more efficient and profitable. Operators sit in a cabin suspended from the trolley, which runs along rails over the ship to lift the cargo. Once the spreader locks onto the container, the container is lifted, moved over the dock, and placed on the chassis either for direct shipment or to the storage yard.

Involve your team and build your specification

Does your terminal close at certain times or does it operate 24/7?

What are the peak performance and reliability that you require?

What type of terminal are you representing, brownfield or greenfield?

What are the physical dimensions of the container ships you currently serve?

Do you anticipate an increase in container throughput?

Are you investigating the possible benefits of automation?

Does your terminal have access to sufficient mains power for STS crane operation?

Yangyumech sales representative can help you develop in-depth answers via a thorough analysis of your case.

Types of Ship-to-Shore (STS) Cranes:

Standard Ship-to-Shore (STS) Cranes:

Designed for traditional container handling operations.

Suitable for Panamax and Post-Panamax vessels.

Super Post-Panamax Cranes:

Built for Ultra-Large Container Vessels (ULCVs) with greater outreach and lifting capacity.

Capable of handling 22+ rows of containers.

Automated Ship-to-Shore (STS) Cranes:

Fully or semi-automated for increased efficiency and reduced labor costs.

Often used in highly automated terminals like those in Rotterdam or Singapore.

Features

High-efficiency loading and unloading function?

Specially designed for the front of container terminal, it can accurately and quickly load and unload containers between ships. It reduces the docking time of ships in harbor and improve the efficiency of harbor cargo throughput.

Automation and Technology:

Advanced automation systems for precise container handling, including remote control and semi-autonomous operation.

Integration with Terminal Operating Systems (TOS) for real-time data exchange and optimized workflow.

Energy Efficiency:

Equipped with regenerative power systems to reduce energy consumption during lowering and braking operations.

Use of variable frequency drives (VFDs) for smoother and more efficient motor control.

Durability and Reliability:

Built to withstand harsh marine environments, including saltwater corrosion and extreme weather conditions.

High-quality materials and components ensure long service life with minimal downtime.

Safety Features:

Comprehensive safety systems, including anti-collision, overload protection, and wind-speed monitoring.

Ergonomic operator cabins with advanced visibility and control systems.

Technical Data

| Main Technical Parameters | |||||||||||

| Basic Parameters | Rated Lifting Capacity | Under Spreader | 35 | 41 | 51 | 65 | t | ||||

| Under Hook | 45 | 50 | 61 | 75 | t | ||||||

| Lifting Height | Above Rail | 37 | 25 | 50 | 35 | 58 | 40 | 62 | 42 | m | |

| Below Rail | 12 | 15 | 18 | 20 | m | ||||||

| Front Outreach | 30 | 45 | 51 | 65 | m | ||||||

| Rear Outreach | 10 | 15 | 15 | 25 | m | ||||||

| Rail Gauge | 16 | 16/22 | 30.48 | 30.48 | m | ||||||

| Total Trolley Travel Distance | 56 | 76/82 | 96.48 | 120.48 | m | ||||||

| Inside Clearance Between Legs | ≥17.5 | ≥17.5 | ≥18.5 | ≥18.5 | m | ||||||

| Clear Height of Middle Cross Beam | ≥13 | ≥13 | ≥13 | ≥13 | m | ||||||

| Distance Between Gantry Bumpers | ≤27 | ≤27 | ≤27 | ≤27 | m | ||||||

| Speed Parameters | Lifting Speed | Full Load | 50 | 60 | 75 | 90 | m/min | ||||

| No Load | 120 | 120 | 150 | 180 | m/min | ||||||

| Trolley Traveling Speed | 180 | 210 | 240 | 240 | m/min | ||||||

| GantryTraveling Speed | 45 | 45 | 45 | 45 | m/min | ||||||

| Boom Hoisting Time (One Way) | 5 | 5 | 5 | 5 | min | ||||||

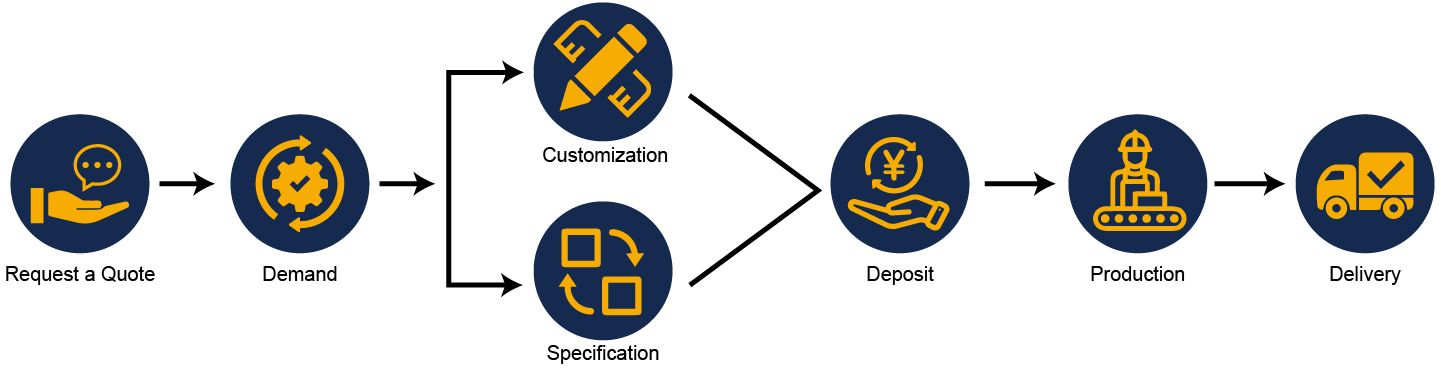

Purchasing process