Home > Crane Parts > Manual column-mounted cantilever crane

Manual column-mounted cantilever crane

The manual column-mounted cantilever crane is a small-scale lifting device widely used in industrial production, warehousing, logistics, and other fields. With its unique structure and operating method, it plays a crucial role in specific applications. In terms of structural composition, it primarily consists of a column, cantilever, manual drive mechanism, and lifting hoist. The column serves as the structural foundation of the entire device and must possess sufficient strength and stability to ensure the crane remains stable and does not sway or tip during operation; the boom can rotate around the column, expanding the scope of lifting operations, with its length varying according to different operational requirements; the manual drive mechanism enables lifting and lowering of loads and rotation of the boom through manual operation, offering simple and intuitive control; the hoist block works in conjunction with the hook to suspend and lift heavy objects. In terms of operating principle, the manual column-mounted cantilever crane leverages the principles of leverage and pulley systems to reduce effort. By manually operating the drive mechanism, the operator moves the lifting chain or steel wire rope, enabling the lifting and lowering of heavy objects. Additionally, the cantilever can rotate 360 degrees around the column, facilitating the movement of heavy objects to different positions and meeting the requirements of multi-angle lifting operations. In terms of application scenarios, manual column-mounted cantilever cranes are commonly used for handling small parts within workshops, lifting heavy objects during assembly processes, and loading/unloading goods in warehouses. For example, in mechanical processing workshops, they can assist workers in moving heavy workpieces to machine tool workbenches; in automotive repair workshops, they can be used to lift engines and other components.

Description

A manual column-mounted cantilever crane is a light-duty lifting device, mainly consisting of a column, a 360° rotatable cantilever, a manual drive mechanism, and a hoist trolley. Its operation relies on manual operation of the drive mechanism, which uses chains or steel wires to drive the hook to lift and lower heavy objects, while utilizing the rotation of the cantilever to achieve horizontal transfer of the load.

The device is characterized by its flexibility and compact structure, allowing it to operate freely in confined spaces. It is easy to operate and requires no complex training to get started. It is also cost-effective, with relatively low manufacturing, installation, and maintenance costs.

It is widely used in scenarios such as the transportation of small parts in workshops, the lifting of heavy objects during product assembly, and the loading and unloading of goods in warehouses. It is particularly suitable for small and medium-sized enterprises to improve operational efficiency and is a practical alternative to large lifting equipment.

Features

Extreme flexibility is one of its core strengths. The device has a compact overall structure and is equipped with a 360° rotating arm, allowing it to operate flexibly in confined spaces such as narrow workshop corners and warehouse aisles, easily avoiding obstacles and enabling multi-angle transfer of heavy objects. It is particularly suitable for work scenarios with high space utilization requirements.

Another major highlight is the low operating threshold. There is no need for complex electrical control systems; the drive mechanism is operated entirely by human power. Operators can quickly learn how to use it after simple instruction, eliminating the time and cost of professional skills training. This is particularly beneficial for small and medium-sized enterprises with high staff turnover.

Cost efficiency is maintained throughout the entire life cycle of the equipment. The manufacturing process does not require complex parts, resulting in relatively low costs. Installation is simple, does not require large-scale infrastructure, and can be put into use quickly. Later maintenance is also more convenient, with low parts replacement costs, significantly reducing the operational burden on enterprises.

The structural design is practical, with columns providing stable support and cantilevers and hoist trolleys working together precisely and efficiently. While ensuring lifting performance, the equipment is also lightweight, meeting basic needs such as small parts handling and assembly hoisting without wasting resources.

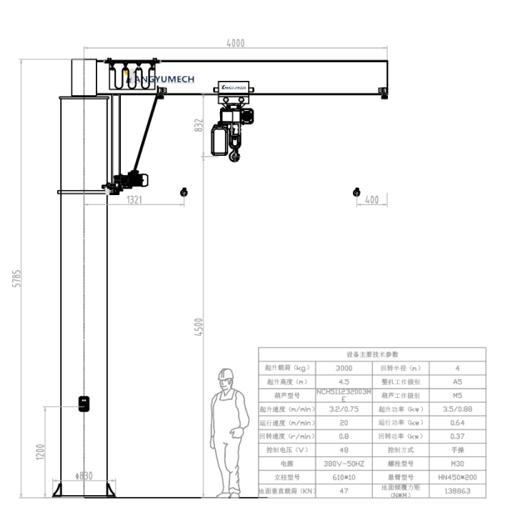

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Span | 2-4m | 2.5-4.5m | 3-5m | 3.5-6m | Customization | |||

| Lifting height | 3-5m | 3-6m | 4-6m | Customization | ||||

| Work Duty | A2-A3 | A3 | A3-A4 | Customization | ||||

| Lifting speed | 0.1-0.3(手动) | 0.05-0.2(手动) | 0.05-0.15(手动) | 0.05-0.1(手动) | ||||

| Hoist Traveling Speed | 0.1-0.3(手动推拉) | 0.05-0.2(手动推拉) | 0.05-0.15(手动推拉) | 0.05-0.1(手动推拉) | ||||

| Crane Traveling Sprrd | 无 | |||||||

| Rail | 无(固定立柱) | |||||||

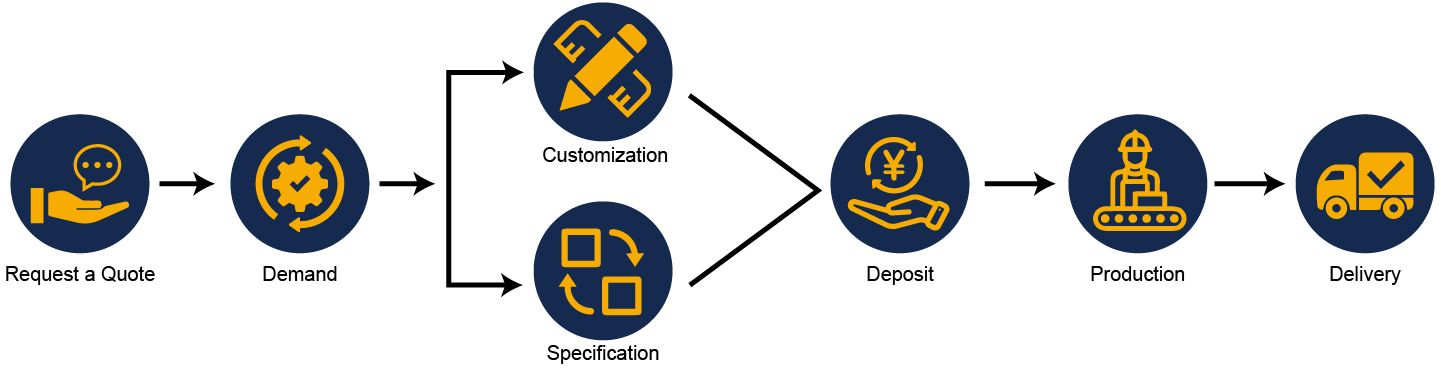

Purchasing process