Home > Products > Port Crane > Ship Loader

Ship Loader

Ship Loader - Efficient and reliable bulk material handling is critical for smooth port operations. That's why Yangyumech provide expertly designed ship loaders that seamlessly integrate with your port infrastructure and ensure optimal performance for your specific requirements.

Loading capacity: 1,000 t/h to 20,000 t/h

Vessel size: 5,000 DWT to 350,000 DWT

Systems specifically designed to your unique requirements

Description

A shiploader is a large machine used for continuously loading bulk solid materials such as iron ore, coal, fertilizers, grains and/or material in bags onto ships or barges. These machines are located in ports and jetties to facilitate bulk material exportation. Generally shiploaders are engineered to suit specific project requirements. Those requirements often include: port design, material characteristics, loading capacity, vessel type.

When selecting and designing a ship loader, the quality and properties of the bulk material, local conditions, performance parameters and environmental requirements play a decisive role.

With these aspects in mind, our engineers determine the most effective and cost-efficient handling principle while minimising operational and maintenance requirements. The customised loading system must fit in your port infrastructure and match current and future vessel sizes. Whether it’s coal, aggregates, mineral compounds, or other bulk materials, our ship loading systems deliver robust performance to keep your operations running smoothly.

Features

Rail-mounted mobility

Our rail-mounted ship loaders include a tripper car supplying material to be conveyed which is generally located either between the rails or beyond the landside running rail of the ship loader. Depending on specific customer and/or environmental requirements, we are able to shield the tripper car and pier conveyor belt from the external environment with an enclosed pier bridge.

Rotating or swiveling functionality

For applications in which vessels are loaded on a finger pier with double-sided berthing, we are able to equip our ship loaders with a rotating or swiveling function. In this instance, the tripper car and pier conveyor belt are located between the rails of the ship loader, with the advantage that the ship loader and tripper car can all run on one rail. For piers with unilateral berthing and vessels with predominantly upright loading hatches, a non-rotating ship loader with a shuttle boom is employed. In this instance, the tripper car is installed on a separate pier bridge beyond the landside running rail of the ship loader and runs on independent rails.

Fixed or stationary solutions

Fixed ship loaders are generally employed in instances where environmentally hazardous material is to be loaded. A significant advantage of these machines is the excellent encapsulation of the feed route so that there is virtually no release of material into the environment – together with protection of the feed material from the elements. The drawback of these machines is that, in many instances, the vessel must be moved, either forward or back, for the purposes of loading into a different hatch.

Technical Data

|

Ship Loader-------------------------------------Technical Specification |

||||

|

Items |

MS30 |

MS100 |

MS180 |

Unit |

|

Rate productive capacity |

300 |

1000 |

1800 |

t/h |

|

Limit capacity |

360 |

1200 |

2000 |

t/h |

|

Bulk cargo |

Coke |

Bulk cement |

Coal |

|

|

Ship size |

5000 |

5000 |

5000 |

DWT |

|

Width of belt conveyor |

1000 |

1400 |

1400 |

mm |

|

Speed of belt conveyor |

2.5 |

2.42 |

3.5 |

m/s |

|

Chute extending length |

8.15 |

19.5 |

19.5 |

m |

|

Chute extending length speed |

9.3 |

4 |

3.6 |

m/min |

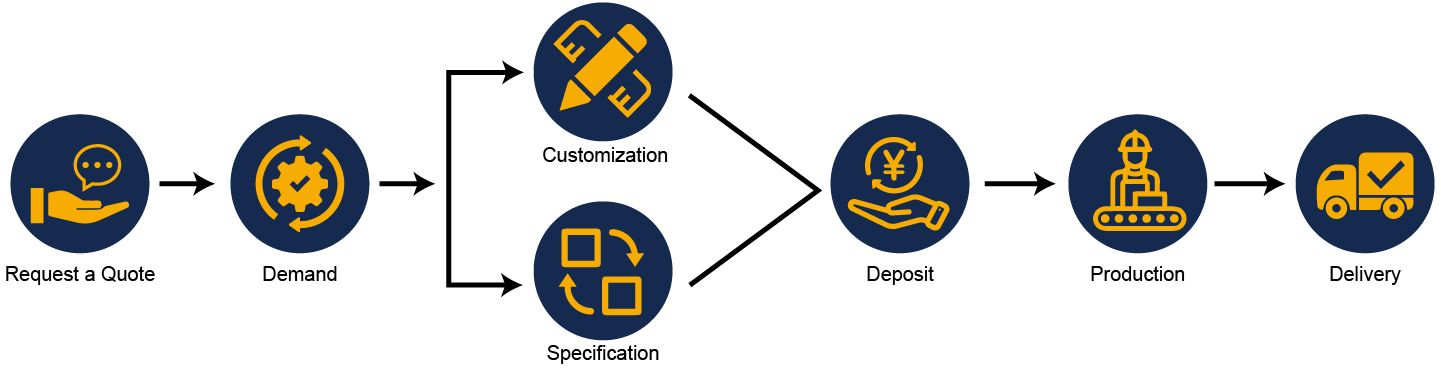

Purchasing process