Home > Products > Overhead Crane > QZ Grab Bucket Overhead Crane

QZ Grab Bucket Overhead Crane

The grab bucket overhead crane has the lifting capacity around 5 to 50 tons together with the weight of the grab bucket, which is widely used in power station, storage, workshop, and port to load and unload scattered objects.

Lifting Capacity:5~50t

Span:10.5~36.5m

Working Duty:A6

Ambient Temperature:-20~40℃

Description

Double girder overhead crane with grab consists of girders, crane traveling mechanism, trolley, electric system and grab. Double girder overhead crane with grab is widely used in power stations, warehouses, workshops and ports to grab or lift bulk materials. The lifting capacity includes the weight of grab and the grab opening direction is parallel or vertical to the main girders.

Bridge (main beam and end beam): supports the crane structure and moves horizontally along the track.

Hoisting mechanism: controls the vertical lifting of the grab bucket, usually equipped with double drums (supporting the opening and closing and lifting of the grab bucket respectively).

Grab bucket: double-flap grab bucket (granular materials) or multi-flap grab bucket (scrap steel, irregular materials) can be selected according to the material type.

Operating mechanism: includes a large car (longitudinal movement) and a small car (lateral movement) to achieve precise positioning in three-dimensional space.

Electrical system: frequency conversion control, anti-sway technology, overload protection, etc. to ensure smooth and safe operation.

Features

The cross-section of the main beam is analyzed using the ANSYS finite element calculation method to ensure sufficient strength, rigidity, and overall stability.

The operator cabin is designed to meet various functional needs, being durable, safe, and reliable, while also providing good visibility, comfort, and an aesthetically pleasing environment, ensuring a pleasant experience for the operator during use.

The grab bucket crane is equipped with a complete set of safety devices, including overload limiters, safety guards, height limiters, and travel limiters.

The hoisting mechanism is easy to operate, stable in performance, and highly productive.

The company is equipped with comprehensive testing facilities, including magnetic particle inspection, ultrasonic testing, and impact testing machines, to ensure product quality.

Technical Data

| Lifting capacity(t) | 5 | 10 | 16 | 20 | |

| Span(m) | 10.5-31.5 | 16.5-31.5 | |||

| Lifting height(m) | 20 | 18 | 28 | 26 | |

| Working class | A6 | ||||

| Speed (m/min) |

Hoist lifting | 39.2 | 40.7 | 41.8 | 48.6 |

| Trolley traveling | 44.6 | 45.9 | 38.0 | 37.8 | |

| Crane traveling | 93.6/113.6 | 112.5/101 | 88/87.3 | 87.3 | |

| Power supply | 380V, 50HZ, 3 phase or others | ||||

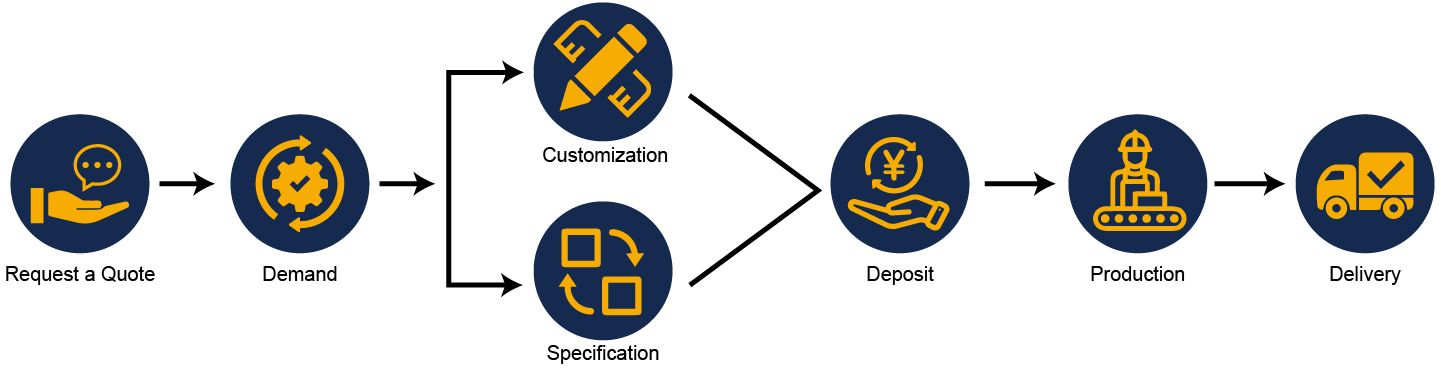

Purchasing process