Home > Products > Overhead Crane > LHB type explosion-proof hoist double bridge crane

LHB type explosion-proof hoist double bridge crane

LHB explosion-proof electric hoist bridge crane is used in conjunction with HB (BCD), HBS (BMD) explosion-proof electric hoist or explosion-proof chain hoist. The lifting capacity is 1 ton, 2 tons, 3 tons, 5 tons, 10 tons, 163.2 tons, 20/5 tons, 32/5 tons (T), etc. The span is 7.5-22.5 meters, and we can also design and manufacture non-standard tonnage and span.

Working level: A4-A5

working environment: -25~+40°

Description

Explosion-proof electric hoist crane standard

It is designed on the basis of "LH electric hoist bridge crane" in accordance with "explosion-proof electrical equipment for explosive environment" and "flameproof electrical equipment for explosive environment"d", and has the characteristics of reasonable structure, beautiful appearance and strong explosion-proof performance.

Explosion-proof electric hoist crane application scope

The products are widely used in factories, warehouses, material yards and other flammable, explosive and corrosive workshops in chemical units. There are two operating modes: ground and driver's cab (usually ground wired button operation, and can also be equipped with a wireless explosion-proof remote control operation). The driver's cab is divided into open and closed types, the installation form is divided into left and right, and the entry direction is divided into side and end, for users to choose according to their respective usage .

Explosion-proof Electric Hoist Crane Description

Product Name: Explosion-proof Electric Hoist Bridge Crane

Alias: explosion-proof bridge crane/overhead crane/crane/hanging crane/hanging car

Model specification:LHB

Category: Explosion-proof double-beam bridge

Product Origin: China

Non-standard customization: Non-standard manufacturing is possible

Power type: three-phase AC 380V-50HZ

Is it in stock: Customized production

Production cycle: 20~40 days

Packing form: None

Supply range: Worldwide

Delivery method: Self-pickup/freight forwarding

Installation: Installation is charged separately

After-sales service: one-year warranty

Features

1. Double-beam bridge crane operating room has three types: separate type, closed type and heat-insulated type.

2. The entrances to the control room platform of a double-beam bridge crane are divided into three types: side, end and top.

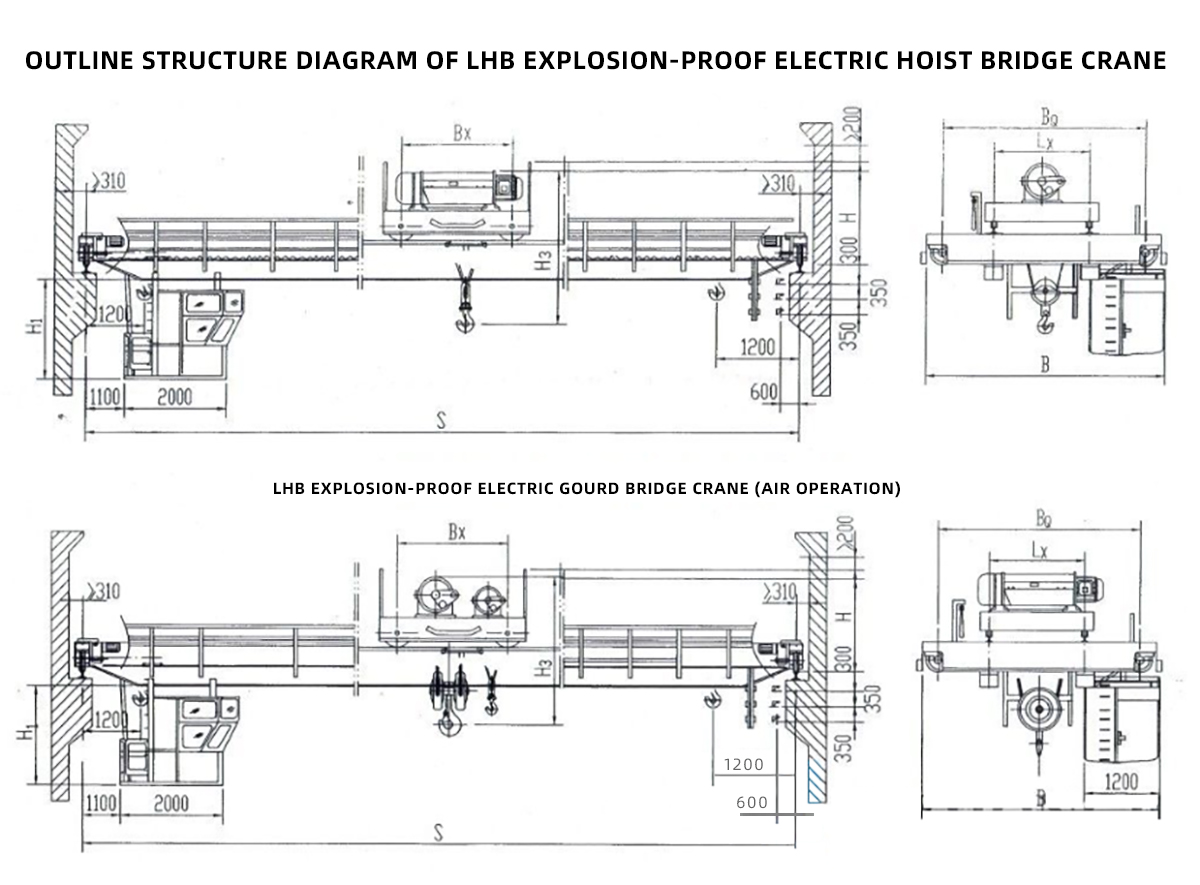

3.H is the height added by the trolley buffer.

4. Double-beam bridge cranes are divided into indoor and outdoor types. When ordering, the high and low temperatures of the working environment and the type of power supply and other technical requirements should be indicated.

5. The addition of overload limiter, large screen display and various protection devices further increases the safety during use.

6.Double girder bridge cranes are generally operated in the air, which is different from other ground-operated cranes. In the air operation, there is a separate small operation room under the crane, while in the ground operation, the operator uses a remote control to operate the crane.

Technical Data

Technical parameters and main dimensions of LHB 3-ton explosion-proof electric hoist bridge crane

| Rated lifting capacity | t | 3 | |||||||||||

| Operation mode | Air or ground exercises | ||||||||||||

| speed | Lifting | m/min | 8 8/0.8 | ||||||||||

| Car operation | 20 | ||||||||||||

| Cart operation | ground | 20 | |||||||||||

| Control room | 20 | ||||||||||||

| Electric Motor | Lifting | Model/kw | BZD132-4/4.5 BZDS1-0.4/4.5 | ||||||||||

| Car operation | BZDY21-4 0.8X2 | ||||||||||||

| Cart operation | ground | BZDY21-4 0.8×2 | BZDY22-4 1.5×2 | BZDY22-4 1.5×2 | |||||||||

| Control room | BZDY22-4 1.5×2 | BZDY22-4 1.5×2 | |||||||||||

| Electric hoist | model | HB(BCD)HBS(BMD) | |||||||||||

| Lifting height | m | 6 | 9 | 12 | 18 | ||||||||

| Work system | A4~A5 | ||||||||||||

| power supply | Three-phase AC 50Hz 380(660)V | ||||||||||||

| Recommended rails | Kg/m | 38~43 | |||||||||||

| span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||

| Maximum wheel pressure | KN | 25.3 | 38.6 | 49.5 | 57.3 | 66.7 | 80.5 | 92.1 | 110 | 124.3 | |||

| Deadweight | Ground Control | t | 4.6 | 5.2 | 6.3 | 7.4 | 9.5 | 12.5 | 14.9 | 17.6 | 19.9 | ||

| Closed control room | 5.4 | 6 | 7.1 | 8.2 | 10.3 | 13.3 | 15.6 | 18.4 | 20.7 | ||||

| Basic size | B | mm | 3600 | 3900 | 4200 | 4600 | |||||||

| BQ | 3200 | 3400 | 3700 | 4100 | |||||||||

| Lx | 1400 | ||||||||||||

| H1 | The air operation is 2300, and there is no such size for ground operation | ||||||||||||

| H3 | 1200 | ||||||||||||

| U | 10c0 | 1Ac0 1c00 | |||||||||||

Technical parameters and main dimensions of LHB 5-ton explosion-proof electric hoist bridge crane

| Rated lifting capacity | t | 5 | |||||||||||

| Operation mode | Air or ground exercises | ||||||||||||

| speed | Lifting | m/min | 8 8/0.8 | ||||||||||

| Car operation | 20 | ||||||||||||

| Cart operation | ground | 20 | |||||||||||

| Control room | 20 | ||||||||||||

| Electric Motor | Lifting | Model/kw | BZD141-4/7.5 BZDS1-0.8/7.5 | ||||||||||

| Car operation | BZDY1 21-4 0.8X2 | ||||||||||||

| Cart operation | ground | BZDY22-4 0.8×2 | BZDY22-4 1.5×2 | BZDY22-4 1.5×2 | |||||||||

| Control room | BZDY22-4 1.5×2 | BZDY22-4 1.5×2 | |||||||||||

| Electric hoist | model | HB(BCD) HBS(BMD) | |||||||||||

| Lifting height | m | 6 | 9 | 12 | 18 | ||||||||

| Work system | A4~A5 | ||||||||||||

| power supply | Three-phase AC 50Hz 380(660)V | ||||||||||||

| Recommended rails | Kg/m | 38 43 | |||||||||||

| span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||

| Maximum wheel pressure | KN | 44 | 51.5 | 58.5 | 65.1 | 77.9 | 89.4 | 100.9 | 116.4 | 124.3 | |||

| Deadweight | Ground Control | t | 5 | 5.7 | 7 | 8.3 | 11.1 | 13.7 | 16.1 | 19.2 | 21.8 | ||

| Closed control room | 5.8 | 6 .5 | 7.8 | 9.1 | 12.1 | 14.5 | 16.9 | 20 | 23.1 | ||||

| Basic size | B | mm | 3600 | 3900 | 4200 | 4700 | |||||||

| BQ | 3200 | 3400 | 3700 | 4100 | |||||||||

| Lx | 1400 | ||||||||||||

| H1 | The air operation is 2300, and there is no such size for ground operation | ||||||||||||

| H3 | 1200 | ||||||||||||

| U | 10c0 | 1Ac0 1c00 | |||||||||||

If you need more technical parameters of other lifting weights,please feel free to contact us.

Purchasing process