Home > Products > Gantry Crane > Semi Gantry Crane

Semi Gantry Crane

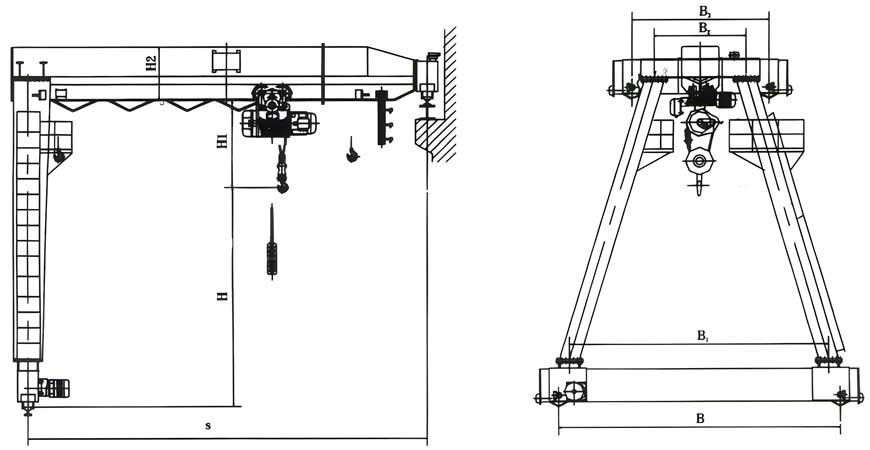

Compared with the overhead crane, Semi Gantry Crane saves the workshop space occupied by pillars; Compared with the gantry crane, it saves the production space; One side is support leg, the other side is end carraige as overhead crane, making better use of the plant structure. Semi Gantry Crane is one cost-effective crane solution!

Capacity: 2t-40t; Span length: 15-30m

Lifting height: 6-12m,etc.; Work duty: A3-A6

Raged voltage: 220V~690V, 50-60Hz, 3ph AC

Reference Price Range:$6000-100000/set

Description

Work environment temperature: -25℃~+40℃, relative humidity ≤85%; Crane control mode: Pendant control / Wireless remote control / Cabin control

Semi-type gantry cranes (BMH type, BMG type) are used with CD1, MD1, other types of electric hoist or LH hoist trolley or QD trolley. It is suitable for lifting, transporting, loading and unloading in open-air operation sites such as stations, wharves, warehouses, construction sites, cement product yards, machinery or structural assembly yards, power stations, etc. It is also suitable for working in indoor workshops.

The support legs of the semi-gantry crane have a height difference, which can be determined according to the civil construction requirements of the use site.

It is composed of lifting mechanism and trolley, single main beam (or double main beam) , support leg, and end carraige, electric control box, operating system, and safety protection system, etc.

Semi gantry crane is a special form of Gantry Crane. Just as shown in the picture, at one side of the crane, this gantry crane for sale runs on an elevated runway system like a overhead crane along the length of the factory.

At the other side, it just runs like a standard rail mounted gantry crane. This special overhead gantry crane for sale allow you extend your workplace by not needing a runway system from the top of the building.

Compared with gantry crane, it uses the structure of the plant instead of a new leg of the crane itself. Undoubtedly, it owns a more cost effective. Considered that semi gantry crane doesn't depend entirely on the plant, this special structure gantry crane has an advantage on the flexibility over EOT crane.

BMH type 2-20t electric hoist semi-gantry crane

There are two typical applications:

Indoors, it is often used under the existing overhead cranes to provide more hooks, thus improving the productivity of your factory.

Outdoors, often is used near the building, making full use of the existing runway structure, thus improving the cost efficient of your factory or plant.

Depending on the loading capacity, this special kind gantry crane can be formed in single girder gantry cranes, as well as double girder gantry crane. So, if you want to see more technical parameters, you can just get a reference from corresponding Overhead Cranes or Gantry Cranes.

Features

Compact Structure

Good Rigidity

Safety and Reliability

Easy Operation

Convenient Installation

Easy Transportation

Technical Data

| Span(rail to rail center) | 6m~data required | ||||||

| Cantilevers | According to your demand, but not more than 1/3 of span | ||||||

| Lifting height | as required | ||||||

| Capacity | 3t, 5t | 1 0t | 1 5t, 16t | 20t, 25t | 30t, 32t | ||

| Lifting speed(m/min) | 8, 8/0.8 | 7/0.7 | 3.5,3.5/0.35 | 4, 4/0.4 | 3,3/0.3 | ||

| Cross travelling speed(m/min) | 10or 20 | 10 or 20 | 10 or 20 | 10or 20 | 10 or 20 | ||

| Long travelling speed(m/min) | 20, 30 | 20, 30 | 20, 30 | 20, 30 | 20, 30 | ||

| Duty Class | A3/A5 | ||||||

| Power source | 380V, 50HZ, 3 phase (or other standard) | ||||||

| Power supply mode | Cable reel / Bus bar | ||||||

| Control model | Pendant pushbutton control, cabin control or remote control | ||||||

Purchasing process