Home > Crane Parts > Motor Reducer

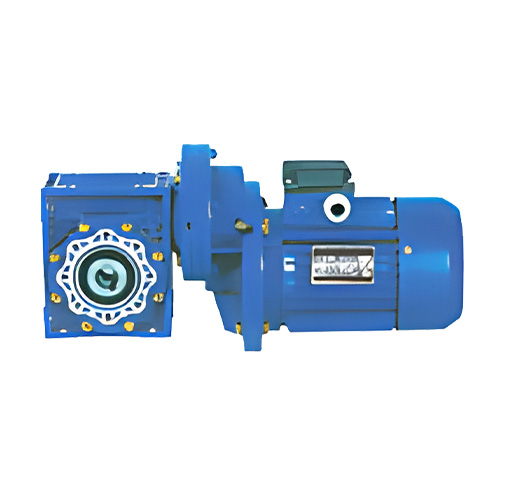

Motor Reducer

The reduction motor is widely used in metallurgy, mining, light industry, chemical steel, cement, printing, sugar, food, rubber, pickles, construction, lifting and transportation, fans and other industries, and can be used to match imported equipment.

Description

Motor reducer refers to the integration of reducer and motor (motor). This integration is also usually called gear motor or gear motor. It saves space, is reliable and durable, has high overload capacity, and the power can reach more than 95KW. Low energy consumption, superior performance, and the reducer efficiency is as high as more than 95%. Small vibration, low noise, high energy saving, high-quality forged steel materials, rigid cast iron box, and high-frequency heat treatment of gear surface. After precision machining to ensure shaft parallelism and positioning accuracy, all of which constitute the gear transmission assembly. The gear reducer motor is equipped with various motors, forming a mechatronics, which fully guarantees the quality characteristics of the product. The product adopts a serialized and modular design concept and has a wide range of adaptability. This series of products has a very large number of motor combinations, installation positions and structural solutions, and can choose any speed and various structural forms according to actual needs.

Features

The coaxial helical gear reducer motor has a compact structure, small size, beautiful appearance, and strong overload bearing capacity.

The transmission ratio is finely graded, with a wide selection range and a wide speed spectrum, ranging from i=2-28800.

Low energy consumption, superior performance, the reducer efficiency is as high as 96%, with low vibration and low noise.

Strong versatility, easy use and maintenance, low maintenance cost, especially for production lines, only a few spare internal transmission parts are needed to ensure the maintenance of normal production of the entire line.

The new sealing device is adopted, with good protection performance and strong environmental adaptability, and can work continuously in harsh environments such as corrosion and humidity.

Technical Data

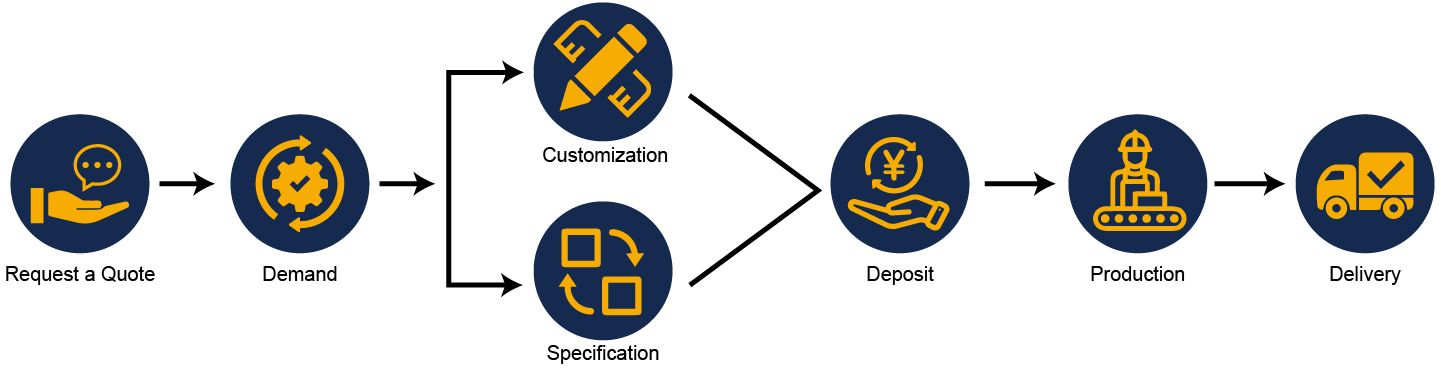

Purchasing process