Home > Crane Parts > KBK Rigid Crane

KBK Rigid Crane

KBK steel cranes are a practical choice for medium-to-small loads and multi-scenario material handling thanks to the reliability of their steel structure, flexible layout capabilities, and stable performance, providing powerful support for efficient transportation in industrial production.

The advantages lie in durability and adaptability. Steel structures are highly resistant to wear and deformation, capable of withstanding certain harsh environments, and have a long service life. Installation does not require complex pre-embedded foundations, allowing flexible suspension from roofs or supports. When adjusting the layout according to production needs in the future, modifications are convenient and costs are controllable, enabling seamless integration with production lines, robots, and other equipment to form an efficient material handling system.In terms of safety and maintenance, the system is equipped with safety devices such as overload protection and limit switches, complying with relevant safety standards. Steel components have a high degree of standardization, making replacement of wear-prone parts convenient. Routine maintenance primarily involves inspecting the tightness of connection components and lubricating parts, resulting in relatively low maintenance costs.

Description

KBK steel cranes are lightweight material handling equipment with high-strength steel components at their core. With their reliable structure and strong adaptability, they are widely used in industrial production for medium and small load transfer scenarios.

From a structural perspective, its core components include steel tracks, running trolleys, electric hoists, and suspension devices. Steel tracks are typically made of cold-rolled steel or welded steel, primarily using high-strength steel grades such as Q235 and Q345, which offer excellent rigidity and load-bearing capacity. The tracks can be flexibly assembled using standardized connectors to form various layouts such as straight lines, loops, and curves, with spans ranging from 2 to 10 meters. They can be customized to suit the layout of workshops or warehouses and specific operational requirements. The suspension system securely anchors the tracks to roof steel structures, concrete beams, or independent supports. Installation does not require complex pre-embedded foundations, making it highly adaptable to various site conditions. In terms of performance, the KBK steel crane has a standard lifting capacity of 0.125-5 tons, with custom models available to accommodate larger tonnage requirements. It is capable of handling various materials such as electronic components, automotive parts, and small machinery. The hoisting mechanism is typically equipped with an electric hoist, with a hoisting speed of 3-16 m/min. The travel trolley moves along the track at a speed of 10-30 m/min, offering high positioning accuracy for precise material handling and placement. Its duty cycle is typically rated at A1-A3, suitable for low to medium-frequency operations with daily working hours ≤8 hours. The stability of the steel structure ensures slow performance degradation over extended use, enabling reliable performance for daily material handling tasks.

The significant advantage of cranes lies in the balance between durability and flexibility. Steel tracks and components exhibit strong resistance to wear and deformation, enabling them to withstand harsh environments such as dust and minor vibrations, resulting in a longer service life. Additionally, the modular design facilitates easy retrofitting and expansion. For instance, adjusting the operational range only requires adding or removing track modules, with modification costs significantly lower than those of traditional cranes. Furthermore, it can seamlessly integrate with production lines, robot workstations, and other equipment to establish an automated material handling system, effectively enhancing overall operational efficiency.

In terms of safety, KBK steel cranes are equipped with safety components such as overload protection devices, lifting height limiters, and trolley travel limiters as standard, complying with EN 13000 and relevant domestic safety standards to provide reliable protection during operation. Daily maintenance is also relatively simple, mainly involving checking the tightness of connecting parts and the lubrication of tracks, resulting in low maintenance costs.

Features

High-strength track design: The tracks are made of high-strength steel such as Q235 and Q345, formed through cold rolling or welding processes, with cross-sections in the shape of channels or I-beams. Compared to ordinary structural steel, their bending strength is increased by over 30%. Within a span of 2–10 meters, the deflection under rated load is ≤L/200, ensuring smooth operation. For example, 5-ton-class tracks have a thickness of 8-12 mm, capable of withstanding long-term, high-frequency load impacts.

Modular assembly system: Core components such as tracks, trolleys, and connectors are standardized steel modules that can be quickly connected using bolts and clips, eliminating the need for on-site welding. A single system weighing less than 5 tons can be installed in just 1-2 days, and the track length can be flexibly extended or the layout changed (e.g., from straight to circular) as needed. The assembly accuracy is ±2 mm, ensuring smooth trolley operation.

Sturdy suspension structure: The suspension device uses forged steel or high-strength bolts and can be directly fixed to concrete beams, steel structure roofs, or independent brackets, with a single-point suspension load capacity of 1-3 tons. The suspension spacing can be adjusted according to the track span (usually 3-5 meters per point) to ensure that the track does not sag significantly and is suitable for different factory structures.

Light-load high-efficiency operation: Lifting capacity ranges from 0.125 to 5 tons (standard models), with custom models capable of handling larger tonnages. Lifting speed: 3–16 m/min (electric hoist drive), travel speed of the running trolley: 10–30 m/min, positioning accuracy: ±5 mm. Ideal for the “point-to-point” transportation of delicate materials such as electronic components and precision parts, avoiding the power waste associated with traditional cranes.

Low-consumption, durable design: Steel components are zinc-plated or painted to prevent rusting for at least 10 years and can withstand workshop dust, light oil stains, and other environmental conditions. The motor uses an S3-40% duty cycle, suitable for low to medium frequency operations (average daily use ≤ 8 hours), with a temperature rise of ≤ 70K during continuous operation to ensure long-term stable operation.

Work level compatibility: Mostly A1-A3 level, specially designed for intermittent handling, such as loading and unloading on production lines and short-distance transportation in warehouses. Its structure has reasonable redundancy and can achieve more than 100,000 lifting cycles under rated load, with a failure rate of less than 0.5 times per thousand hours.

Highly compatible with any site: No need for pre-embedded tracks or fixed foundations. Tracks can be hung along walls or roofs, or installed on the ground. The minimum working space width required is only the track span + 1.5m, making it suitable for narrow workshops and old factory renovations. For example, a 2m span KBK steel crane can be installed next to a 3m wide assembly line to achieve lateral material transfer.

Flexible system integration: Can be linked with conveyor belts, robotic arms, AGVs, and other equipment to build an automated material flow system. For example, in an automotive parts workshop, circular KBK tracks can be used in conjunction with robotic grippers to achieve unmanned transfer of workpieces between multiple workstations, thereby improving production speed.

Controllable renovation costs: When expanding or adjusting the track layout in the future, only the number of modules needs to be increased or decreased, and the renovation costs are 30%-50% of those of traditional cranes. For example, when expanding a straight track to a U-shaped layout, the cost of the new track and connecting parts is approximately 20% of the original system, and does not affect the strength of the original structure.

Multiple safety protections: Standard overload limiter (accuracy ±5%), lifting height limit switch (mechanical + electronic dual protection), trolley travel limit switch, some models equipped with emergency stop button and leakage protection, compliant with EN 13000 and GB/T 3811 standards, preventing safety accidents caused by overload or overtravel.

Convenient and economical maintenance: Steel components are highly versatile, and wear parts (such as small wheels and motor carbon brushes) can be quickly replaced without customization. Daily maintenance only requires monthly checks of track connection tightness and quarterly lubricant replenishment. Annual maintenance costs are less than 20% of those of traditional cranes, making them suitable for low-cost management by small and medium-sized enterprises.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | |

| Span | 2-6m | 2-7m | 3-8m | 3-10m | |

| Lifting height | 2-6m | 2-7m | 3-8m | 3-10m | |

| Work Duty | A2-A3 | A3 | |||

| Lifting speed | 8-16m | 6-12m | 5-10m | 4-8m | |

| Hoist Traveling Speed | 15-30m | 15-25m | 10-20m | ||

| Crane Traveling Sprrd | (单轨无大车)/10-20(双轨) | (单轨无大车)/8-15(双轨) | |||

| Rail | 槽型钢制轨道 | ||||

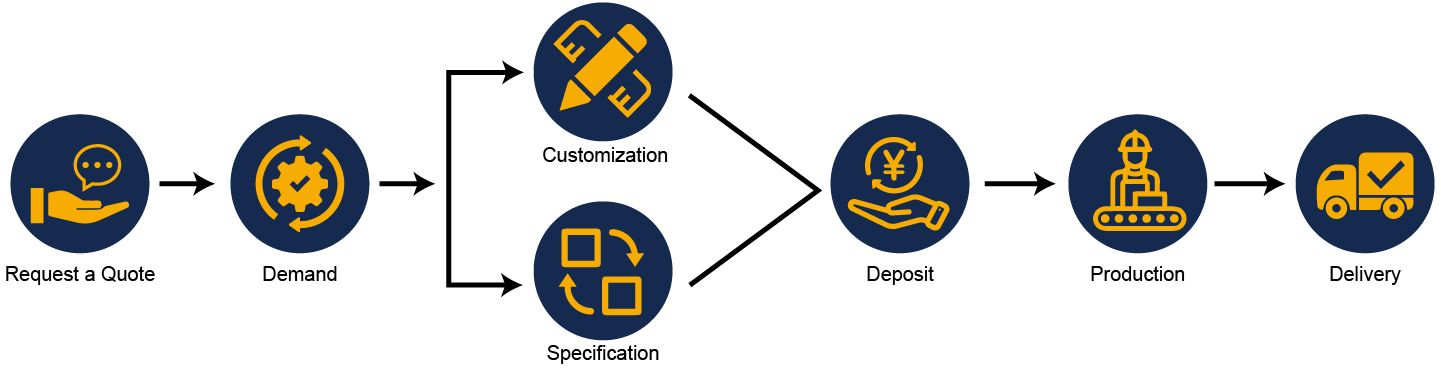

Purchasing process