Home > Products > Gantry Crane > Single Girder Gantry Crane

Single Girder Gantry Crane

Single girder gantry crane is a common type of gantry crane used indoors or outdoors, and it is also an ideal solution for light duty and medium duty material handling. Yangyumech can offer different type design of single girder gantry crane like box girder, truss girder, L shape girder, with low headroom hoist, standard room (monorail) hoist to meet a range of applications. Our products have the characteristics of compact design, light weight, low noise, easy installation, and maintenance.

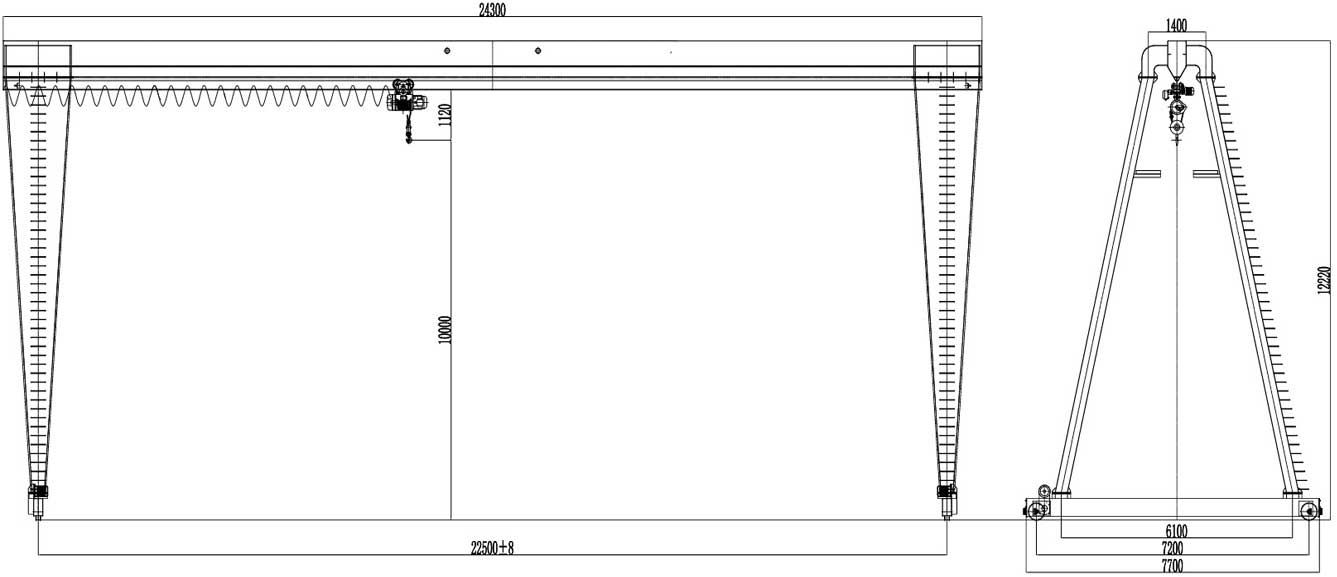

Capacity: 0.3t-36t; Span length: 4-35m

Lifting height: 6m, 9m, 12m, etc.

Raged voltage: 220V~690V, 50-60Hz, 3ph AC

Customized: YES

Description

Single Girder Gantry Crane

Work environment temperature: -25℃~+40℃, relative humidity ≤85%. Crane control mode: Pendant control / Wireless remote control / Cabin control. Reference Price Range: $6000-30000/set

MH type electric hoist gantry crane is designed and manufactured in accordance with national and industry standards such as GB/T3811-2008 "Crane Design Specification" and JB/T5663-2008 "Electric Hoist Gantry Crane". It is a workshop lifting equipment, which uses CD MD electric wire rope hoist or an electric chain hoist as the lifting mechanism. It can be used indoors and outdoors, such as the docks, freight yards, warehouses, and construction sites.

The single-girder gantry crane is mainly composed of a steel structure gantry, a crane traveling mechanism, an electric hoist, and an electric control system. Normally, single girder gantry cranes are most widely used and often in open storage yards. Considering the high quality, we ensure the gantry cranes price we offer is not the lowest but the most reasonable.

Box-type gantry crane: The box-type gantry crane is a box-type structure with the main beam structure, which has the advantages of high speed and high efficiency. The fixed working environment of the site.

Rubber-tyred gantry crane: Product introduction: The tire-traveling gantry crane is a kind of gantry crane that uses tires instead of steel wheels to travel on the basis of the box gantry crane. It has the advantages of high speed, high efficiency and no need to pave the subgrade.

Truss gantry crane: The truss gantry crane is a truss structure with a main beam structure. It has the advantages of advanced structure, reasonable mechanical performance, portability, high rigidity, simple operation, convenient use, safety and reliability, and convenient disassembly.

As one of the experienced gantry crane manufacturers, we can produce different specifications of the crane.

Features

Single Girder Gantry Crane

Follows the international design code, like FEM, CMAA, EN ISO.

Can equip with low headroom hoist or standard room hoist.

The girder is compact, low self-weight, and welded by S355 material, the welding specification follows ISO 15614, AWS D14.1. Deflection can be from 1/700 ~ 1/1000. MT or PT is requested for fillet welding, and UT is requested for joint welding.

The end carriage can be hollow shaft or open gear type design, the wheel is made by alloy steel with proper heat treatment.

Branding gear motor with IP55, F insulation class, IE3 Energy

efficiency, over-heat protection, manual release bar, and electro-magnetic brake feature. The motor is controlled by inverter for smooth running.

The control panel design follow IEC standard, and is installed inside IP55 enclosure with socket for easy Installation.

Double line Galvanized C track festoon system with flat cable, one line for hoist power and signal transmission, one line for the pendent control trolley movement.

SA2.5 Surface pre-treated by blasting according to ISO8501-1; C3-C5 painting system according to ISO 12944-5

Technical Data

Single Girder Gantry Crane

| Rated Load(Kg) | Working Level | Lifting Height | Lifting Speed | Iranversing speed | Traveling Speed | |

| FEM | ISO | M | M/Min | M/Min | M/Min | |

| 3000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 5000 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 6300 | 1AM-4M | M3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 8000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 10000 | 1AM-4M | IM3-M6 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 12500 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/5 | 2~20 | 3~30 |

| 16000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 20000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.66/4 | 2~20 | 3~30 |

| 25000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

| 32000 | 1AM-3M | M3-M5 | 6/9/12/15/18 | 0.8/3.2 | 2~20 | 3~30 |

Purchasing process