Home > Products > Overhead Crane > European-style double-girder bridge crane

European-style double-girder bridge crane

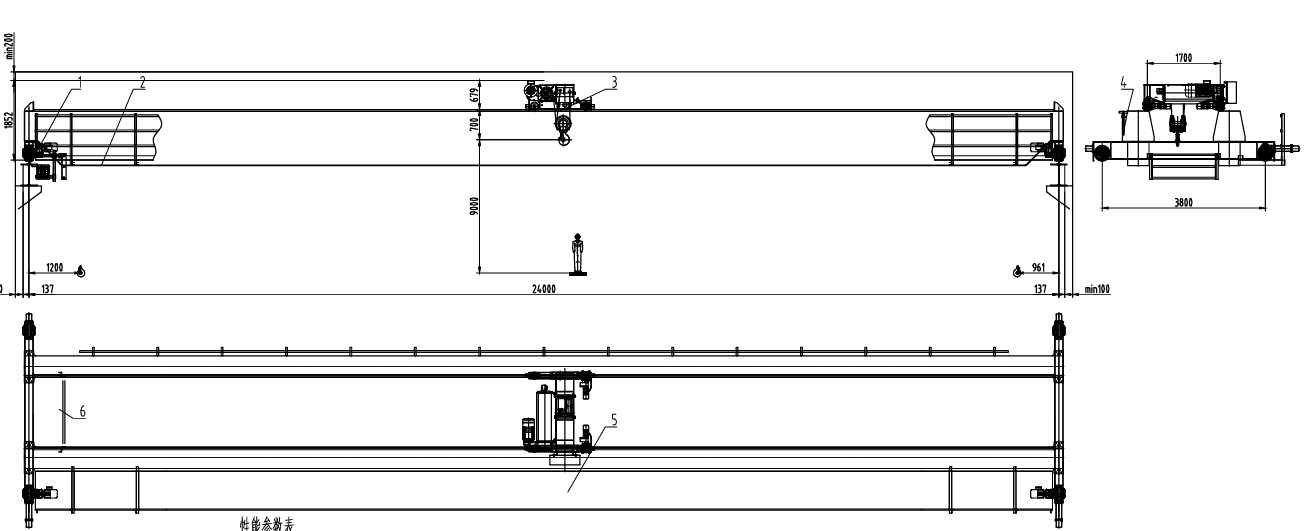

European-style double-girder bridge cranes are lifting equipment that integrates advanced European design concepts and technology. They feature a compact structure, light self-weight, and low wheel load, effectively saving factory space and reducing foundation load requirements. Its core parameters include lifting capacity, lifting height, span, duty cycle (related to daily operating hours), distance from track surface to lowest point of roof, voltage and frequency, travel speed of main and auxiliary hoists, and lifting speed of the hoisting mechanism. In terms of configuration, customers can choose whether to install full-vehicle variable frequency drives and whether to equip a secondary hook (if required, the lifting capacity of the secondary hook must be specified), flexibly meeting the requirements of different operational scenarios.

Description

1.The European double-girder bridge crane is a high-end lifting device that integrates advanced European design standards and technical processes. It is specially designed for industrial material handling scenarios and combines efficiency, stability, and space adaptability.

2.Its structure is optimally designed to be compact and lightweight, with low wheel pressure, effectively reducing the load requirements on the factory building structure and saving working space.

3.Core performance parameters include lifting capacity (customizable according to requirements), lifting height, span, duty cycle (related to daily working hours, suitable for different levels of workload), and the distance from the track surface to the lowest point of the roof. Additionally, precise operational parameters such as the travel speed of the main crane, the travel speed of the trolley, and the lifting speed of the hoisting mechanism are provided to ensure strong controllability during operations.

4.With advanced technology and reasonable structural design, this crane is widely used in industrial fields such as machinery manufacturing, metallurgy, warehousing, and chemical engineering. It can efficiently complete various tasks such as hoisting, transporting, and loading/unloading heavy objects, and is a key piece of equipment for improving logistics efficiency and ensuring operational safety in modern industrial production.

5.Supports wireless or wired controller operation, adapting to different operating habits.

Features

Optimized structure in accordance with European standards, lighter overall weight, and lower wheel pressure effectively reduce requirements for factory track foundations and roof load-bearing capacity, saving factory construction and renovation costs. Particularly suitable for old factories or work environments with limited space.

Pay attention to the detailed design of key structural dimensions (such as the distance from the track surface to the lowest point of the roof), which can be flexibly adjusted according to different factory layouts to reduce space conflicts with factory columns, beams, and other facilities, thereby improving the utilization rate of the working area.

Equipped with a high-precision transmission system and variable frequency control technology (optional full-vehicle variable frequency control), the speed adjustment of the large and small vehicles and lifting mechanisms is smoother, enabling precise positioning of heavy objects, reducing shaking during operation, and lowering the risk of material damage.

Supports multiple work levels (related to daily working hours), from intermittent operations to high-frequency continuous operations, and can handle them all with stability, meeting the operational intensity requirements of different industries such as machinery manufacturing, metallurgy, and warehousing.

Core parameters such as lifting capacity, lifting height, span, and operating speed can be customized according to actual needs, covering material handling scenarios of different weights, heights, and distances.

Supports auxiliary hook configuration (auxiliary hook lifting capacity can be specified) to enable a single device to lift materials of different weight levels.

The remote control can be selected in wireless or wired handle mode to suit different operating habits and working environments (such as dusty or noisy environments).

Integrated with multiple safety devices such as overload protection, limit protection, and emergency braking, this system reduces safety risks caused by operational errors or equipment failures, ensuring the safety of personnel and materials.

Key components are designed using standardized, modular designs, facilitating routine maintenance and component replacement, reducing maintenance downtime, and lowering long-term operational costs.

With the above features, this crane is widely used in industrial settings such as machine shops, metallurgical workshops, large warehouses, and chemical industrial parks. It can efficiently complete various heavy lifting tasks such as equipment hoisting, raw material transfer, and finished product loading and unloading, making it a core piece of equipment for improving logistics efficiency in modern industrial production.

Technical Data

| Capactit | 1t | 2 | 3.5t | 5t | 10t | 16t | 20t | |

| Lifting height | 6-12m | 8-16m | 6-30m | 6-24m | ||||

| Work Duty | A3-A4 | A3-A5 | A4-A5 | A5-A6 | ||||

| Lifting Speed | 8/0.8m/min | 5/0.8m/min | 0.8/5m/min | 0.6-4m/min | ||||

| Hoist Trave Speed | 20-30m/min | 20-40m/min | ||||||

| Crane Traveling Speed | 30-40m/min | 30-45m/min | 30-60m/min | |||||

| RAil | P22 | P22-P30 | P30-P38 | P38-QU70 | P38-QU80 | |||

| span | 6-12m | 6-16m | 8-18m | 10.5-31.5m | ||||

Purchasing process