Home > Crane Parts > KBK Flexible Crane

KBK Flexible Crane

With its modular construction, lightweight operation, flexible adaptability, and low maintenance costs, the KBK flexible crane is the ideal choice for medium-to-small loads, high-frequency, high-precision handling scenarios. It can effectively improve the efficiency and intelligence of material transfer in automated production line upgrades.

Flexibility and adaptability are its key advantages. Track installation requires no pre-embedded foundations and can be suspended from various structures, making it easy to retrofit. The cost is only 30%-50% of that of traditional cranes, and it can quickly adapt to changes in production lines. It can also be integrated with other equipment to form an automated system, enhancing operational efficiency.In terms of safety and maintenance, it is equipped with multiple safety protection devices, complies with multiple safety standards, and features high component standardization with strong interchangeability of wear parts, resulting in low maintenance costs. The annual maintenance expenses are less than 20% of those for traditional cranes.

Description

The KBK flexible crane is a lightweight material handling device designed around a modular concept, widely used in workshops, warehouses, production lines, and other settings. Its flexible and efficient characteristics make it an ideal choice for handling medium and small loads. Its core structure consists of C-shaped steel tracks, suspension devices, running trolleys, and electric hoists. The C-shaped steel tracks serve as the foundation for both load-bearing and operation, manufactured from high-strength steel with characteristics of lightweight and high rigidity. They can be flexibly assembled into various layouts such as straight lines, loops, and curves using connecting components, with spans ranging from 2 to 10 meters. This allows for quick adjustments to accommodate different operational spaces based on site requirements. The suspension system secures the tracks to the roof or support structures, offering easy installation and removal, and strong adaptability to site modifications.

In terms of performance, the KBK flexible crane has a lifting capacity range of 0.125-5 tons, meeting the material handling needs of medium and small loads. The hoisting mechanism primarily uses electric hoists, with a hoisting speed of 3-16 m/min, a travel speed of the running trolley of 10-30 m/min, and positioning accuracy of ±5 mm, enabling precise material handling and placement, particularly suitable for precision operation scenarios. The work class is A1-A3, capable of handling low to medium-frequency operations with an average daily operation time of ≤8 hours. During operation, the noise level is ≤75 dB, providing a quiet working environment. The crane's key advantage lies in its modular design, which offers high flexibility and low-cost modification capabilities. Tracks and related components can be standardized for production and assembly, resulting in a short installation period. If adjustments to the operational range are needed in the future, simply adding or removing track modules is sufficient, with modification costs amounting to only 30%-50% of those for traditional cranes. Additionally, the equipment is standardly equipped with overload protection devices and limit switches, compliant with EN 13000 safety standards, ensuring operational safety throughout the process.

In terms of application scenarios, KBK flexible cranes are suitable for industries with high requirements for handling precision and environmental conditions, such as automotive parts manufacturing, electronics manufacturing, and pharmaceutical processing. They can efficiently complete material loading, unloading, transfer, and stacking tasks, helping production lines achieve automated upgrades and improve overall operational efficiency.

Features

C-shaped steel track core: Utilizes high-strength cold-rolled C-shaped steel tracks (typically made of Q235 or Q345 steel), featuring a channel-shaped cross-section, with a self-weight of only 1/3 to 1/2 that of traditional I-beam tracks (e.g., a 5m span track weighs ≤50kg/m) The tracks are assembled using standardized connectors (bolts, clamps) and can be configured into straight, circular, curved, suspended, or ground-mounted layouts. The span is flexible, covering 2-10m, and is suitable for irregular sites.

Highly integrated components: Core components (rails, running trolleys, electric hoists) are standardized modules that do not require complex welding. They can be quickly assembled with bolts during installation. The installation period for a single system weighing less than 5 tons is less than two days, which is more than 60% shorter than that of traditional cranes.

Light Load Efficiency: Lifting capacity of 0.125-5 tons, focusing on the handling of medium and small loads, lifting speed of 3-16 m/min (electric hoist drive), travel speed of 10-30 m/min, positioning accuracy of ±5 mm, suitable for the transportation of delicate materials such as electronic components and precision parts, avoiding the efficiency waste of traditional cranes “overkill for small loads.”

Low energy consumption and quiet operation: The motor uses variable frequency speed control technology, reducing energy consumption by 20%-30% compared to traditional lifting equipment. Running parts (such as trolley wheels) are made of wear-resistant nylon material, which, combined with the smooth surface of the track, keeps operating noise at ≤75dB, well below the workshop environment noise standard (≤85dB), making it suitable for pharmaceutical and food workshops with high noise requirements.

Work level compatibility: A1-A3 level design, optimized for low to medium frequency operations (≤8 hours per day), motor operating mode S3-40%, suitable for intermittent loading and unloading on production lines, short-distance transportation in warehouses, and other scenarios, without the high maintenance costs associated with heavy-duty cranes.

Convenient site modification: The tracks can be suspended from the roof steel structure, concrete beams, or independent supports, eliminating the need for embedded tracks or fixed foundations and minimizing damage to the factory building. If the scope of operations needs to be expanded in the future, simply add or remove track modules. The modification cost is only 30%-50% of that of a traditional crane, making it particularly suitable for manufacturing industries that frequently adjust their production lines.

Diverse layout: Supports single-track, double-track, circular track, and other combinations, and can be seamlessly integrated with conveyor belts and robot workstations to form an automated material flow system. For example, in an automotive parts workshop, circular KBK tracks can be used to transport materials between multiple workstations, reducing manual intervention.

Multiple safety protections: Standard overload limiter (accuracy ±5%), lifting height limiter (dual mechanical and electronic protection), trolley travel limiter, emergency stop button and leakage protection on some models, compliant with EU EN 13000 and domestic GB/T 3811 standards, ensuring safe operation.

Low maintenance costs: Components are highly standardized, and wear parts (such as small wheels and motor carbon brushes) are highly versatile and can be replaced without customization. The track surface is galvanized for corrosion resistance with a service life of ≥10 years. Routine maintenance only requires regular inspection of the tightness of connecting parts and lubrication, with annual maintenance costs less than 20% of those of traditional cranes.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | |

| Span | 2-6m | 2-7m | 3-8m | 3-10m | |

| Lifting height | 2-6m | 2-7m | 3-8m | 3-10m | |

| Work Duty | A2-A3 | A3 | |||

| Lifting speed | 8-16m | 6-12m | 5-10m | 4-8m | |

| Hoist Traveling Speed | 15-30m | 15-25m | 10-20m | ||

| Crane Traveling Sprrd | (单轨无大车)/10-20(双轨) | (单轨无大车)/8-15(双轨) | |||

| Rail | C型钢轨道 | ||||

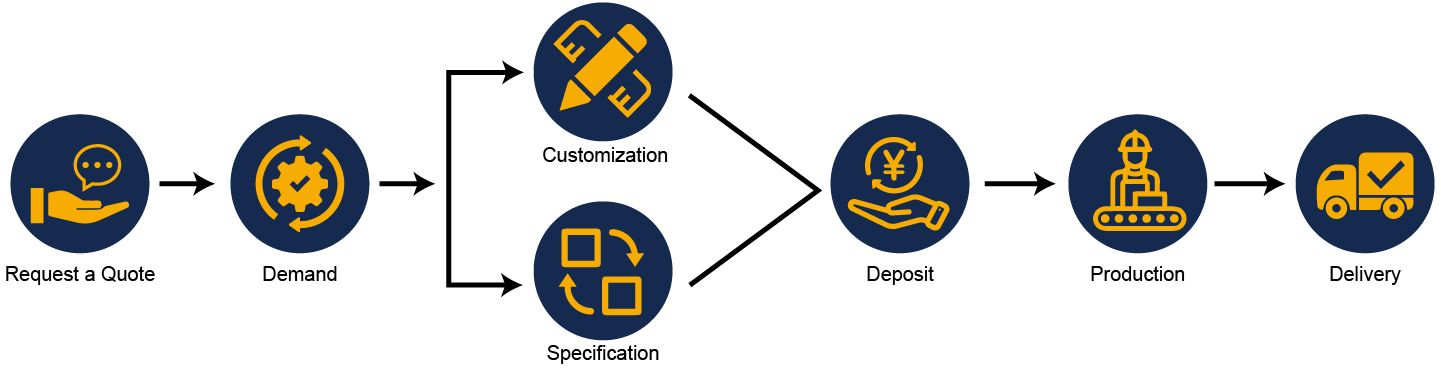

Purchasing process