Home > Crane Parts > Full-frame single-girder gantry crane

Full-frame single-girder gantry crane

The full truss-type single-girder gantry crane is a common type of gantry crane. It is widely used in outdoor warehouses, material yards, ports, construction sites, and other scenarios due to its lightweight structure and high cost-effectiveness. It is mainly used for loading, unloading, transporting, and short-distance transfer of materials. Its core feature is the use of a “truss-type” gantry structure and single-girder load-bearing form, which combines flexibility and practicality.

Description

The fully truss-type single-girder gantry crane is a lifting device specifically designed for outdoor work scenarios. Its core advantage lies in its unique lightweight truss structure.

This structure is composed of structural steel, which not only significantly reduces the weight of the equipment and reduces the load requirements on the foundation, but also has minimal wind resistance due to its hollow design. In open-air sites such as ports, terminals, and open-air storage yards, it can maintain stable operation and avoid affecting operational safety due to strong winds.

In terms of performance, the crane adopts a single-beam load-bearing design and uses high-strength steel as the main beam material, which not only ensures structural rigidity but also provides good stability, easily meeting lifting requirements ranging from 1 to 20 tons.

With a span of 8-30m and a lifting height of 6-18m, it can be flexibly adapted to a variety of scenarios, such as cargo transfer in warehousing and logistics, raw material loading and unloading in steel processing plants, and component hoisting at construction sites.

In terms of installation and transportation, the full-frame single-girder gantry crane adopts a modular assembly model, with each component transported separately, reducing transportation costs and difficulties, and making on-site assembly more convenient and efficient.

In terms of operational performance, it is rated at A3-A5 and equipped with a variable frequency speed control system, which enables smooth adjustment of lifting and running speeds, reducing load sway. It also comes standard with safety limit devices, such as lifting height limits and running travel limits, to ensure comprehensive operational safety and efficiency.

Compared with traditional gantry cranes, fully truss-type single-girder gantry cranes are ideal for outdoor lifting operations due to their excellent ventilation, light weight, and high cost performance. Their advantages are particularly evident in situations where equipment flexibility and environmental adaptability are highly demanded.

Features

Made of structural steel, it significantly reduces the weight of the equipment, thereby reducing the load requirements on the foundation and lowering site construction costs.

Excellent aerodynamic performance: The hollow design minimizes wind resistance, enabling stable operation in open, windy environments such as ports, terminals, and open-air storage yards. This prevents strong winds from affecting operational safety and improves applicability in complex weather conditions.

Wide load capacity range: Featuring a single-beam load-bearing design and utilizing high-strength steel as the main beam material, this structure ensures both structural rigidity and excellent stability, easily accommodating lifting requirements ranging from 1 to 20 tons.

Flexible operation coverage: With a span coverage of 8-30m and a lifting height of 6-18m, it can be flexibly adapted to various scenarios such as cargo transfer in warehousing and logistics, raw material loading and unloading in steel processing plants, and component hoisting at construction sites, meeting the needs of different operation spaces.

Reliable working level: Working level is A3-A5, which can adapt to different frequencies and intensities of work tasks, balancing work efficiency and equipment durability.

Smooth speed control system: Equipped with a variable frequency speed control system, it can smoothly adjust the lifting and running speeds, reducing load swaying, protecting the lifted cargo, and improving the accuracy of operations.

Modular assembly mode: Each component can be transported separately, reducing transportation costs and difficulties, which is especially suitable for sites with limited transportation conditions. At the same time, on-site assembly is more convenient and efficient, shortening the equipment installation and commissioning cycle and enabling rapid commissioning.

Technical Data

| Capactit | 1t | 2 | 3.5t | 5t | 10t | 16t | 20t | |

| Lifting height | 6-12m | 6-14m | 8-16m | 8-18m | 8-20m | 10-20m | ||

| Work Duty | A3-A4 | A4-A5 | A5 | |||||

| Lifting Speed | 8/0.8m/min | 6/0.6m/min | 5/0.5m/min | 4/0.4m/min | ||||

| Hoist Trave Speed | 20-30 | 20-35 | 25-40 | |||||

| Crane Traveling Speed | 25-40 | 30-50 | 30-60 | |||||

| RAil | P20-P24 | P22-P28 | P24-P30 | P28-P38 | P38-QU70 | QU70-QU80 | QU80-QU100 | |

| span | 8-16m | 8-18m | 10-20m | 10-22m | 12-25m | 12-28m | 12-30m | |

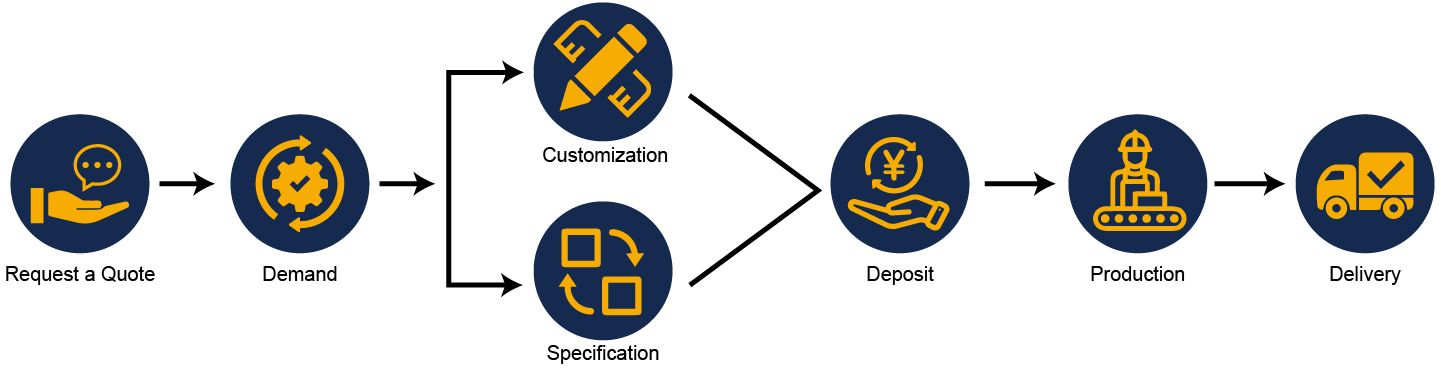

Purchasing process