Home > Products > Gantry Crane > Aluminum alloy small gantry

Aluminum alloy small gantry

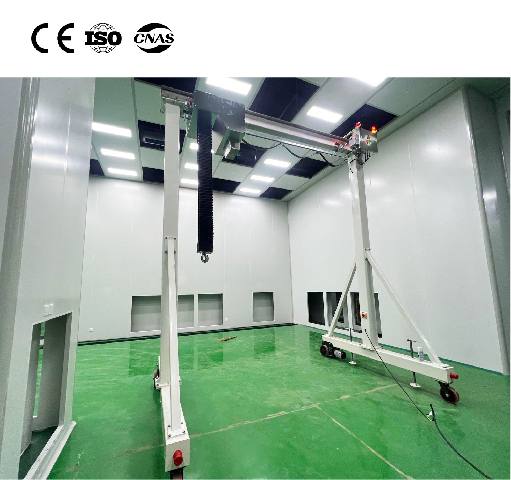

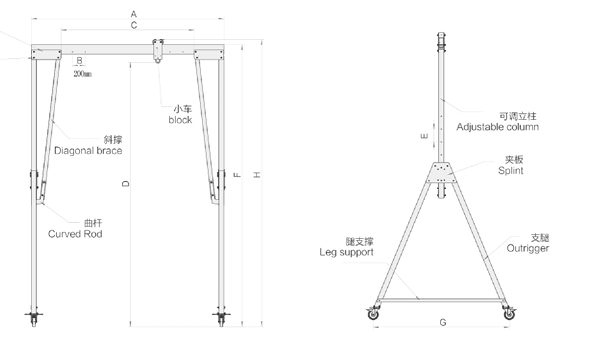

The aluminum alloy small gantry crane is a lightweight lifting device made from high-strength aluminum alloy as its core material. With its “lightweight + portable” characteristics, it plays a significant role in small-scale lifting applications. Its structure is simple, typically consisting of two aluminum alloy columns, a crossbeam, and swivel casters at the bottom. The overall weight is only 1/3 to 1/2 of that of a steel-made small gantry crane of the same specification (e.g., approximately 50-80 kg for a 1-ton model). It can be manually disassembled and assembled quickly, and can be transported by a single person, making it suitable for narrow spaces such as workshop corners or laboratories. In terms of performance, the lifting capacity ranges from 0.5 to 3 tons, the span covers 1.5 to 4 meters, the lifting height is 1.2 to 3 meters, and the work class is typically A2 to A3. It is suitable for light-load, low-frequency cargo handling (such as small equipment, molds, and components). The lifting mechanism is typically equipped with a manual hoist or small electric hoist (lifting speed: 3–8 m/min), and the bottom swivel casters feature a braking function, ensuring flexible mobility and reliable stability. They are widely applicable in various scenarios, including electronics factories, food processing plants, laboratories, and maintenance facilities where equipment weight and cleanliness are critical. They can replace manual handling for labor-saving operations while avoiding the drawbacks of steel equipment, such as rusting and heavy weight, making them a flexible and practical solution in the lightweight lifting field.

Description

The aluminum alloy small gantry crane is a portable lifting device designed specifically for light-duty lifting applications. With its unique material and structural design, it offers significant advantages in the field of small cargo handling.

In terms of material and structure, it is constructed using high-strength aluminum alloy, a material choice that reduces its weight to just 1/3 to 1/2 of that of a steel-made small gantry crane of the same specifications, significantly enhancing the equipment's portability. The overall structure is simple, consisting primarily of an aluminum alloy main beam, legs, and bottom swivel casters. The span typically ranges from 1.5 to 4 meters, with a lifting height of up to 1.2 to 3 meters. It can flexibly adapt to narrow spaces such as workshop corners, laboratories, and small warehouses without occupying excessive floor space. In terms of performance, the aluminum alloy gantry crane has a lifting capacity ranging from 0.5 to 3 tons, easily handling the transportation of small equipment, components, and materials. The lifting mechanism offers two options: manual hoist or electric hoist, with a lifting speed of 3 to 8 meters per minute, allowing flexible switching based on operational requirements. The bottom is equipped with swivel casters with braking functionality, enabling the equipment to move with great flexibility and easily change work positions. During operation, it can be securely fixed in place to ensure operational safety. Its work class is A2-A3, suitable for light-load, low-frequency work scenarios.

The aluminum alloy material gives the equipment excellent corrosion resistance and rust prevention properties, making it suitable for use in environments with high cleanliness requirements, such as electronics factories, food processing plants, and pharmaceutical laboratories. Additionally, the equipment is easy to assemble and transport, with a single person able to complete the operation, significantly reducing labor and time costs.

With its light weight, flexibility, efficiency, and cleanliness, the aluminum alloy small gantry crane is the ideal choice for light lifting applications, providing powerful support for small cargo handling operations.

Features

High-strength lightweight design: Utilizing high-strength aluminum alloy profiles such as 6061-T6, the weight is only 1/3 to 1/2 that of a steel-made gantry crane of the same specification (e.g., the self-weight of a 3-ton model is approximately 200 kg), allowing for single-person handling and significantly reducing labor costs. Aluminum alloys have a superior strength-to-weight ratio compared to ordinary steel, ensuring lightweight design while meeting lifting requirements of 0.5-3 tons.

Corrosion and rust resistance: The surface is anodized to resist corrosion from humid, acidic, and alkaline environments, eliminating the risk of rust. It is suitable for places with high cleanliness requirements, such as electronics factories, food workshops, and medical laboratories, to prevent steel equipment from rusting and contaminating materials.

Compact and space-saving design: With a span of just 1.5–4 m and a lifting height of 1.2–3 m, the overall dimensions are ideal for narrow areas such as workshop corners, laboratories, and small warehouses. The minimum operational footprint is less than 6 m², eliminating the need for dedicated lifting channels.

Modular assembly: The main beam and legs are connected by quick-release bolts, allowing assembly or disassembly to be completed in 10-15 minutes. After disassembly, it can be folded for storage (some models have extendable legs), saving storage space and facilitating vehicle transportation.

Flexible mobility and stability: The base is equipped with swivel casters with brakes (diameter 100-150mm) as standard, with a pushing resistance of ≤50N, allowing for easy adjustment of the working position; the braking system can instantly lock the wheels, ensuring stability of the crane body during lifting operations, with an overturn resistance coefficient of ≥1.5. Diverse lifting options: Supports manual hoist (lifting speed 3-5 m/min) or electric hoist (5-8 m/min) configurations to accommodate different operational efficiency requirements. The electric model is equipped with a wireless remote control, enabling remote operation within a 30m range for enhanced convenience. Low-frequency, high-compatibility design: The work class is A2-A3, specifically designed for light-load, low-frequency scenarios (e.g., daily operation ≤ 2 hours). Components such as the motor and hoist adopt simplified yet reliable solutions to balance cost and practicality.

Cleanroom-specific: No paint peeling, no rust contamination, compliant with GMP certification standards, suitable for direct contact with precision materials in pharmaceutical manufacturing facilities, semiconductor cleanrooms, and similar environments. Temporary lifting applications: Replaces the fixed hook limitations of manual chain hoists, enabling rapid deployment in scenarios such as temporary cargo unloading in warehouses, equipment maintenance in workshops, and instrument relocation in laboratories, without requiring pre-installed tracks or fixed foundations. Outdoor Temporary Operations: Aluminum alloy offers superior UV resistance and aging performance compared to steel, making it suitable for short-term outdoor use (e.g., exhibition setup, outdoor maintenance) without concerns about material degradation. When paired with a waterproof electric hoist, it can withstand light rain conditions.

The aluminum alloy small gantry crane has core competitiveness in “lightweight portability + clean corrosion resistance + flexible adaptability,” filling the gaps in lightweight, cleanliness, and spatial adaptability of steel lifting equipment. It has become an efficient solution for 0.5-3t light lifting scenarios, offering “instant installation and use, ready to go whenever needed.”

Technical Data

| Capacity | 1t | 2t | 3.5t | |

| Span | 1.5-3 | 2-3.5 | 2.5-4 | |

| Lifting height | 1.2-2.5 | 1.5-2.8 | 1.8-3 | |

| Work Duty | A2-A3 | A3 | ||

| Lifting speed | 3-5(手动)/5-8(电动) | 3-5(手动)/5-6(电动) | ||

| Hoist Traveling Speed | 手动推拉 | 手动或电动葫芦平移 | ||

| Crane Traveling Sprrd | 3-5(人力推动) | 2-4(人力推动) | 2-3(人力或电动辅助推动) | |

| Rail | 带刹车万向轮 | |||

Purchasing process