Home > Products > Gantry Crane > Double-girder tire crane

Double-girder tire crane

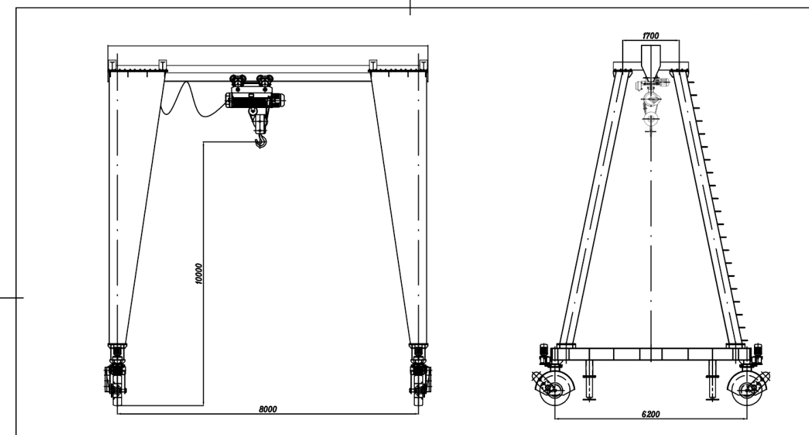

Dual main beam load-bearing reinforcement: Utilizing two parallel box-type or truss-type main beams connected by cross beams to form a rigid frame, the load-bearing capacity is increased by over 50% compared to single-beam tire-mounted cranes, accommodating lifting requirements from 10 to 50 tons (with some custom models reaching 100 tons), The span range is extended to 12-30m, making it suitable for lifting extra-long and extra-wide components such as steel structures and precast panels. Tire-mounted mobility: Equipped with multiple sets of pneumatic tires (typically 4-8 wheels), no fixed tracks are required, allowing free movement on hardened surfaces (concrete, asphalt). The minimum turning radius is approximately 5-8m, enabling rapid relocation between work sites (e.g., from a workshop to a storage yard). Travel speeds reach 10-20 km/h, significantly outperforming the mobility efficiency of track-mounted cranes. Stability system upgrade: Standard-equipped with retractable hydraulic outriggers, which, when deployed during operation, provide a support area 30%-50% larger than single-beam models. Combined with counterweight design, ground pressure can be reduced to 0.1-0.2 MPa, enabling stable operation on non-hardened surfaces (such as compacted soil). The anti-overturning performance meets the GB/T 3811-2008 heavy-duty standard.

Description

The double-girder tire-mounted crane is a lifting device that combines strong load-bearing capacity with high mobility. With its unique structural design and outstanding performance, it plays an important role in a variety of heavy-duty work scenarios.

From a structural perspective, it adopts a double main beam box-type structure, which significantly enhances the overall rigidity and load-bearing capacity of the equipment, enabling it to cover a lifting range of 10-50 tons and easily handle the lifting requirements of heavy equipment, large steel structures, and other heavy objects. At the same time, the large span design of 12-30 meters allows for a wider range of operations and adapts to the space requirements of different sites. In terms of mobility, the crane is equipped with a tire-mounted travel system, completely eliminating the constraints of tracks. The 4-8 wheel drive configuration enables it to adapt to various hardened surfaces, while a travel speed of 10-20 km/h facilitates rapid movement between multiple sites. The minimum turning radius of 5-8 meters ensures flexible maneuverability in narrow spaces, significantly enhancing operational flexibility and efficiency.

To ensure operational stability, the double-girder tire-mounted crane is equipped with retractable hydraulic outriggers as standard. When extended, the outriggers provide a large support area, with ground pressure as low as 0.1-0.2 MPa, enabling stable operation even on unpaved surfaces and significantly reducing requirements for the worksite. The crane achieves a work class of A5-A6, capable of meeting the demands of medium to high-frequency continuous operations while maintaining efficient performance over extended periods. In terms of application scenarios, the double-girder tire-mounted crane is widely applicable in heavy machinery factories, ports, construction sites, and other locations. Whether it involves the installation and commissioning of heavy equipment, the loading and unloading of containers, or the transportation of large prefabricated components, it can efficiently complete these tasks, providing robust lifting support for various industrial production and engineering construction projects.

Double-girder tire-mounted cranes, with their balanced load-bearing capacity and high mobility, are the ideal choice for heavy-duty operations in a variety of scenarios, providing reliable support for improving operational efficiency and ensuring operational safety.

Features

Double-beam box-type structure: Utilizing two parallel box-type main beams (typically made of Q355B high-strength steel), these beams are connected transversely to form a rigid frame, resulting in a torsional stiffness improvement of over 60% compared to single-beam models. This structure enables the equipment to stably support loads ranging from 10 to 50 tons. During operations spanning 12 to 30 meters, the deflection of the main beams is controlled within L/1000, ensuring structural stability during heavy-load lifting operations.

Modular combination design: Core components such as main beams, legs, and walking mechanisms can be disassembled for transportation and assembled on site using high-strength bolts, reducing the installation cycle by 30% compared to integrated models, while also facilitating subsequent maintenance and component replacement.

Tire-mounted trackless mobility: Equipped with a 4-8 wheel hydraulic drive system, the tires are made of engineering-grade wear-resistant rubber (diameter ≥1.2m), enabling free movement on hardened surfaces such as concrete and asphalt, free from track constraints. Travel speed reaches 10-20 km/h, enabling rapid transfer between multiple workstations (e.g., cross-workshop transportation within a factory), offering over 50% better site adaptability compared to track-mounted cranes.

Flexible steering system: With full hydraulic steering and a minimum turning radius of only 5-8m, combined with a dual-direction cab design, it can maneuver flexibly in narrow spaces (such as workshop aisles and port yards), solving the pain point of “difficult turning” for large equipment.

Hydraulic leg reinforcement: Standard configuration includes 4-6 extendable hydraulic legs, which, when extended, provide a support span of 8-12m. By increasing the ground contact area, the ground pressure is reduced to 0.1-0.2MPa (equivalent to one-third that of a standard truck), enabling stable operation even on unpaved surfaces such as compacted soil or gravel sites without the need for additional ground reinforcement.

Dynamic balance control: Some high-end models are equipped with electronic spirit levels and leg pressure sensors that monitor the tilt angle of the machine body (≤3°) in real time. When the tilt angle exceeds the safe range, an alarm is automatically triggered and movement is restricted to prevent the risk of overturning under heavy loads.

High performance level: Generally reaches A5-A6 level, with core components such as motors and reducers designed for heavy-duty applications (e.g., hoisting motor duty cycle S3-60%). It can handle 10-16 hours of medium-to-high-frequency operations daily, making it suitable for continuous production scenarios in heavy machinery factories, ports, and similar environments. Precise speed control: The hoisting mechanism uses variable frequency speed control (speed range 0.5-8 m/min), supporting heavy-duty low-speed smooth positioning and light-duty high-speed efficient transportation; the trolley running speed is 20-40 m/min, and the main crane travel speed is graded by tonnage (10t model 20 km/h, 50t model 10 km/h), balancing efficiency and safety.

Heavy Industry: Used in heavy machinery factories for the installation and commissioning of machine tools and stamping equipment, capable of precisely lifting and installing large components weighing up to 50 tons; Ports and Logistics: Suitable for container yards and bulk cargo terminals, capable of loading, unloading, and stacking 20-40 foot containers; Construction: Used in bridge and wind power projects to transport precast beams, towers, and other oversized components, with outriggers capable of adapting to complex construction site terrain; Emergency Response: Can quickly reach accident sites to assist in the lifting and deployment of rescue equipment, with mobility far exceeding that of tracked cranes.

The double-girder tire-mounted crane combines the triple advantages of “double-girder high load capacity + tire high mobility + stable leg support,” which not only compensates for the insufficient load capacity of single-girder tire-mounted models but also overcomes the high cost of all-terrain cranes. It has become the “best value for money” choice for medium to large-scale heavy-duty and multi-site operations, especially in industrial scenarios that require a balance of efficiency, flexibility, and safety.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Span | 8-14m | 8-16m | 10-18m | 10-20m | 12-22m | 14-25m | 14-28m | |

| Lifting height | 6-10m | 6-12m | 8-14m | 8-16m | 10-18m | 10-20m | 12-20m | |

| Work Duty | A3-A4 | A4 | A4-A5 | A5 | A5-A6 | |||

| Lifting speed | 8/0.8m/min | 6/0.6m/min | 5/0.5m/min | 4/0.4m/min | ||||

| Hoist Traveling Speed | 20-30m | 20-35m | 20-40m | |||||

| Crane Traveling Sprrd | 15-20m | 12-18m | 10-15m | 8-12m | 6-10m | 5-8m | ||

| Rail | 混泥土硬化地面 | 钢筋混泥土地面 | ||||||

Purchasing process