Home > Products > Gantry Crane > Double girder gantry truss crane

Double girder gantry truss crane

A double-girder gantry truss crane is a large lifting device with a double girder gantry as its main load-bearing structure and a truss design. It combines the high load-bearing capacity of a double girder structure with the lightweight characteristics of a truss design, and is widely used in scenarios that require large spans and heavy loads.

The double main beams are supported on the ground tracks by the end beams (gantry legs) at both ends, forming a movable “gantry” frame. The hoisting trolley runs horizontally along the main beam tracks, and the gantry frame as a whole can move longitudinally along the ground tracks, thereby achieving full coverage of the work area.

Unlike single-girder cranes, these cranes have two parallel main girders connected by end beams to form a gantry structure. The double-girder design significantly increases the load capacity of the equipment, enabling it to handle hundreds of tons or even higher lifting capacities. At the same time, it offers superior structural stability and stronger lateral bending and torsional resistance when operating over long spans (typically 20 meters or more).

Description

The double-girder flower rack gantry crane is a large lifting device that combines high-efficiency lifting with stable operating performance.

Its core structure adopts a double main beam truss design, with two main beams and secondary beams made of high-strength steel working together to form a stable load-bearing frame. Not only is it lighter in weight, reducing pressure on the ground foundation, but it also has a strong load-bearing capacity, capable of handling the hoisting of heavy cargo.

In terms of mechanical performance, it is equipped with a precise lifting mechanism, a flexible walking mechanism, and an efficient trolley running mechanism. These three mechanisms work together to lift heavy objects vertically and move them horizontally, ensuring the precision and safety of hoisting and handling operations.

The double-girder design further enhances the overall stability of the equipment, enabling it to maintain good operating conditions even during large-span operations.

Widely applicable, it is often used in container loading and unloading at ports and terminals, ship section hoisting at shipyards, large steel material handling in heavy industrial factories, and building material hoisting at construction sites. With its reliable performance, it provides strong support for various heavy-duty operations.

Features

Double main beam load reinforcement: A truss structure with two parallel main beams is used, forming a rigid support system through a combination of steel trusses, which increases the load capacity by 40%-60% compared to single-beam models. The main beam spacing is adjusted according to the tonnage (e.g., 3.5 m for a 20-ton model), which effectively distributes the load, reduces deflection deformation, and is suitable for long-term heavy-duty operations.

Maintenance convenience design: A dedicated maintenance walkway (width ≥ 0.8 m) is provided between the two main beams, equipped with safety railings and ladders, allowing direct access to core components such as the hoisting mechanism and trolley running mechanism. Routine inspections and maintenance can be performed without the need for additional scaffolding, resulting in a 60% reduction in maintenance labor hours compared to single-beam models.

Multiple safety features: In addition to the standard lift height limit and travel limit, new features include main beam deflection monitoring, wind resistance braking system (such as rail clamps + anchoring devices), and double beam synchronization monitoring. These features comply with the GB/T 3811-2008 heavy-duty safety standard and can be certified by international organizations such as CE and ISO.

Highly customizable adaptability: Can be equipped with dual trolleys (for dual hook coordination), rotating lifting gear (360° rotation), anti-sway system (sway amplitude ≤ 3°), etc., according to operational requirements. It can even be integrated with an automated control system to achieve unmanned operation, making it suitable for high-end applications such as intelligent ports and heavy machinery factories.

Modular assembly: Main beams, legs, flower racks, and other components can be disassembled for transportation and assembled on site using high-strength bolts, reducing the need for hoisting equipment by 50% compared to integral double-beam models. However, due to the increased structural complexity, the installation and commissioning period is 30%-40% longer than that of single-beam models, and requires a professional team to perform precision calibration.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Span | 8-16m | 10-18m | 12-20m | 12-22m | 14-25m | 16-28m | 18-30m | |

| Lifting height | 6-12m | 6-14m | 8-16m | 8-18m | 10-20m | 12-24m | ||

| Work Duty | A4 | A5 | A5-A6 | A6 | ||||

| Lifting speed | 8/0.8m/min | 6/0.6m/min | 5/0.5m/min | 4/0.4m/min | ||||

| Hoist Traveling Speed | 20-30m | 25-35m | 30-40m | |||||

| Crane Traveling Sprrd | 25-40m | 30-50m | 30-60m | |||||

| Rail | p30 | p30-p38 | p38-QU70 | QU70-QU80 | QU80-QU100 | QU100 | QU100-QU120 | |

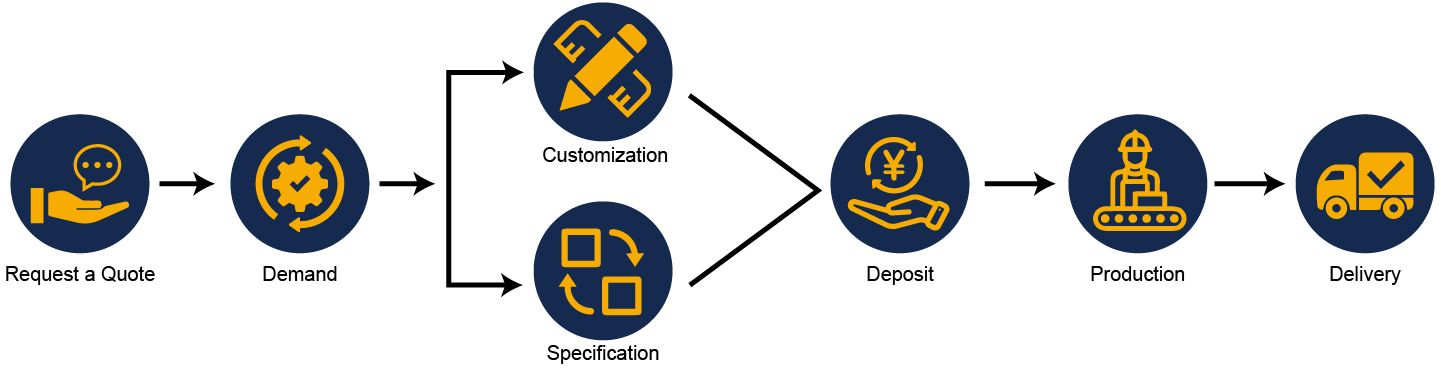

Purchasing process