In industrial lifting scenarios—from small workshops and assembly lines to cleanrooms and logistics centers—the

Electric Chain Hoist stands out as a compact, precise, and reliable solution. Unlike wire rope electric hoists (designed for ultra-heavy loads), electric chain hoists excel at light-to-medium lifting tasks, offering unmatched flexibility and ease of use. This comprehensive guide breaks down everything you need to know about electric chain hoists, including key types (such as EU-standard and cleanroom models), core advantages, and how to choose the right one for your needs—with insights from trusted manufacturers like

Henan Yangyumech Co., Ltd.

An Electric Chain Hoist is a powered lifting device that uses a high-strength alloy steel chain (instead of wire rope) and an electric motor to lift, lower, and position loads. Its compact design, lightweight structure, and precise control make it ideal for scenarios where space is limited or load accuracy is critical—tasks that manual chain hoists or bulky wire rope hoists can’t handle efficiently.

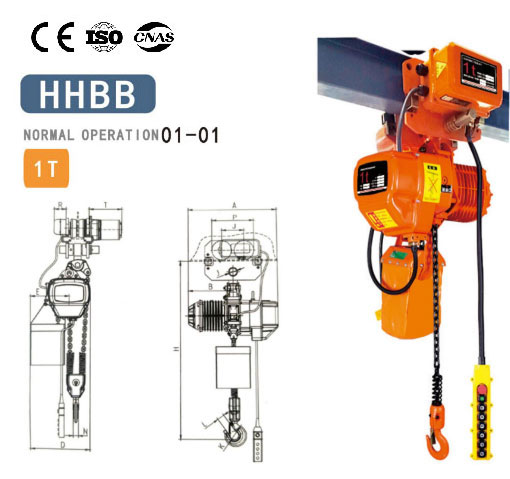

Every reliable electric chain hoist (like those from Yangyumech, a supplier with CE, ISO, and CNAS certifications) includes these essential parts:

- High-strength alloy steel chain: Resists wear, corrosion, and fatigue—common coatings include galvanization or nickel plating for added durability.

- Compact electric motor: Powers chain movement, with efficiency ratings (e.g., IE3 for EU-compliant models) to reduce energy consumption.

- Chain guide & sprocket: Ensures smooth, tangling-free chain operation—critical for maintaining load stability during lifting.

- Dual brake system: Combines electromagnetic and mechanical brakes to secure loads instantly during power cuts or emergencies, complying with EN 12077-1 (European chain hoist safety standard) and ISO 9001.

- Control unit: Pendant controls (for close-range use) or wireless remote controls (for safety in crowded or hazardous areas).

- Mounting options: Ceiling-mounted, wall-mounted, or trolley-mounted (for horizontal movement along KBK tracks or monorails).

Compared to wire rope hoists, manual chain hoists, or other lifting equipment, electric chain hoists offer unique advantages—especially for light-to-medium duty operations:

Electric chain hoists have a slim, lightweight design (typically 10-50 kg for 0.5-5T models) that fits in tight spaces. Unlike wire rope hoists (which require large drums for cable storage), their chain-driven structure eliminates bulky components—perfect for small workshops, mezzanines, or assembly lines with limited overhead space.

The slow, steady chain movement (lifting speeds usually 1-6 m/min) allows for pinpoint load positioning. This is critical for tasks like installing delicate machinery, aligning assembly line components, or handling fragile goods—where even minor swaying could cause damage.

Most electric chain hoists require minimal setup: they can be mounted to ceilings, beams, or portable trolleys in minutes. Lightweight models (≤2T) can even be moved between workstations, making them ideal for flexible production environments.

Alloy steel chains are resistant to wear and corrosion, and sealed gearboxes prevent dust and debris ingress—reducing maintenance needs. With proper care, Yangyumech’s electric chain hoists last 8-12 years, outperforming manual hoists (which often need chain replacement every 2-3 years).

Top-tier electric chain hoists (like Yangyumech’s) meet strict safety standards:

- Overload protection: Shuts down the hoist if the load exceeds the rated capacity (prevents chain snapping).

- Emergency stop button: Instantly cuts power in critical situations (e.g., load instability).

- CE/ISO/CNAS certification: Ensures legal use in global markets, including the EU, North America, and Asia.

Electric chain hoists are categorized by design, compliance, and application. Below are the most widely used types—including industry-leading models from Yangyumech, tailored to diverse industrial needs.

The most versatile option, the Standard Electric Chain Hoist is designed for general-purpose lifting. Key features:

- Load capacity: 0.5T to 10T (covers most light-to-medium industrial tasks).

- Lifting height: 3m to 12m (customizable for taller spaces).

- Control: Basic pendant controls (24V low-voltage for operator safety).

- Best for: Small workshops, retail warehouses, and light manufacturing (e.g., lifting tools, small machinery parts).

For businesses operating in the EU or prioritizing top-tier safety/efficiency, the EU-Standard Electric Chain Hoist (offered by Yangyumech) is a must. Key specs:

- Compliance: Meets EN 12077-1 (safety) and EN 60034 (motor efficiency)—uses IE3 premium motors to reduce energy costs by 15-25%.

- Enhanced safety: Thermal motor protection, anti-drop brakes, and IP54 ingress protection (dust and water-resistant).

- Modular design: Easy to disassemble for maintenance, minimizing downtime.

- Best for: EU-based factories, automotive assembly lines, and businesses exporting to European markets (CE marking is mandatory).

Engineered for sterile environments, the Cleanroom Electric Chain Hoist is ideal for industries where hygiene is critical. Key features:

- Hygienic design: Stainless steel components, smooth surfaces, and oil-free lubricants (complies with EN 1672-2 for food/pharmaceutical safety).

- Low particle emission: Sealed motors and chains prevent dust or debris from contaminating cleanrooms.

- Load capacity: 0.5T to 5T (suited for light sterile tasks).

- Best for: Pharmaceutical plants, food processing facilities, and semiconductor factories.

For horizontal movement, the Electric Chain Hoist & Trolley Set is a game-changer. Key benefits:

- Trolley options: Manual trolleys (for 0.5T-3T loads) or electric trolleys (for 3T-10T loads), compatible with KBK standard tracks or I-beams.

- Smooth travel: Trolley wheels with anti-wear bearings, ensuring quiet, stable horizontal movement.

- Customizable stroke: 3m to 30m (matches workspace dimensions).

- Best for: Large factories, assembly lines, and logistics centers needing flexible load movement (e.g., moving parts between production stations).

A lightweight, portable option, the Mini Electric Chain Hoist is designed for ultra-light tasks. Key features:

- Load capacity: 0.1T to 0.5T (ideal for small-scale lifting).

- Compact size: Fits in backpacks or toolboxes—perfect for home workshops, retail stockrooms, or maintenance tasks (e.g., lifting HVAC components).

- Battery-powered options: Cordless models for areas without power outlets.

- Best for: DIY enthusiasts, small retail stores, and on-site maintenance teams.

Choosing the wrong electric chain hoist can lead to safety risks, operational delays, and unnecessary costs. Follow this guide to match the hoist to your needs:

- Rated Load Capacity: Choose a hoist with a capacity 10-20% higher than your heaviest load (e.g., if your max load is 4T, select a 5T hoist) to avoid overloading.

- Lifting Height: Measure the vertical distance from the hoist’s mounting point to the lowest load position (e.g., 3m for workshops, 8m for high-ceiling warehouses). Ensure the chain length meets this need (add 0.5-1m extra for safety).

- Space: Tight areas (e.g., small workshops) need compact standard models; large spaces need hoists with trolleys.

- Conditions:

- Cleanrooms: Opt for stainless steel cleanroom models (compliant with EN 1672-2).

- EU/Export Markets: Prioritize EU-standard models with CE certification.

- Wet/Dusty Areas: Choose hoists with IP54+ ingress protection (e.g., Yangyumech’s EU-standard model).

- Control Type: Pendant controls for fixed workstations; wireless remotes for large or hazardous areas (e.g., factories with moving machinery).

- Horizontal Movement: If you need to move loads side-to-side, add a trolley (manual for light loads, electric for heavy loads).

- Mounting: Ensure the hoist fits your existing infrastructure (e.g., KBK tracks, I-beams, or ceiling hooks). Yangyumech offers custom mounting brackets for non-standard setups.

- Power Supply: Match the hoist’s voltage (110V, 220V, 380V) to your site’s power—low-voltage controls (24V) are safer for operators.

Choose suppliers like Henan Yangyumech Co., Ltd. that offer:

- Proven Certifications: CE, ISO 9001, and CNAS to guarantee compliance and quality.

- Diverse Product Lines: Standard, EU-standard, cleanroom, and mini models to cover all needs.

- After-Sales Support: Maintenance, genuine spare parts (alloy steel chains, brakes), and technical training.

To extend your hoist’s lifespan, ensure safety, and maintain compliance, follow these best practices:

- Daily Checks: Examine the chain for wear, kinks, or corrosion; test the brakes and emergency stop (critical for preventing accidents).

- Monthly Checks: Inspect the motor for overheating (should not exceed 70°C), clean the chain guide, and tighten loose bolts.

- Annual Servicing: Hire certified technicians (e.g., Yangyumech’s team) to lubricate gears, replace worn brake pads, and calibrate overload protection.

- Lubrication: Use manufacturer-recommended lubricants (e.g., food-grade oil for cleanroom models) every 10-20 operating hours—avoids friction and rust.

- Cleaning: Wipe the chain with a dry cloth after use (use a mild detergent for cleanroom models) to remove debris.

- Replacement: Replace the chain if it has more than 5% broken links (per EN 12077-1) or signs of severe wear (e.g., stretched links).

- Motor Care: Keep the motor clean and well-ventilated—avoid blocking air vents (prevents overheating).

- Control Unit: Store pendant controls in a dry place; replace damaged cables immediately (prevents short circuits).

Never use non-compliant parts (e.g., cheap steel chains, generic brakes)—they void certifications, reduce performance, and risk accidents. Use Yangyumech’s genuine parts: high-strength alloy chains, EN-compliant brakes, and IE3 motors.

Ensure staff are trained to:

- Operate the hoist safely (follow load limits, avoid sudden starts/stops).

- Recognize warning signs (unusual noises, chain slack) and report issues promptly.

- Follow maintenance schedules (critical for compliance with ISO 9001 and EN 12077-1).

A: With proper lubrication and inspection, a genuine alloy steel chain (e.g., Yangyumech’s) lasts 3-5 years. Replace it sooner if there’s wear, corrosion, or broken links.

A: Yes—choose a model with IP54+ ingress protection (e.g., Yangyumech’s EU-standard hoist) to resist rain, dust, and temperature extremes (-10°C to 50°C). Avoid using cleanroom models outdoors.

A: Electric chain hoists use a motor for lifting (saves labor, faster, more precise); manual chain hoists require hand cranking (only for light loads, slow, labor-intensive).

A: Yes—CE marking is mandatory. Yangyumech’s EU-standard electric chain hoist meets EN 12077-1 and EN 60034, ensuring legal compliance.

A: Prices vary by type and capacity: Mini models (≤0.5T) cost $300-$800; Standard models (0.5T-5T) cost $800-$3,000; EU-standard/cleanroom models (1T-10T) cost $3,000-$8,000. Contact Yangyumech for customized quotes.

The Electric Chain Hoist is a versatile, efficient solution for light-to-medium lifting tasks—combining compact design, precise control, and long-term reliability. Whether you need a standard model for workshops, an EU-standard hoist for European markets, or a cleanroom variant for pharmaceutical plants, prioritize certified suppliers like Henan Yangyumech Co., Ltd. Their CE, ISO, and CNAS-marked products guarantee compliance, safety, and after-sales support.

For personalized recommendations (e.g., matching a hoist to your workspace or industry) or to request a quote, contact Yangyumech’s team today—they’ll help you find the perfect electric chain hoist for your needs.

Post Views: 5