In industrial lifting, construction, and logistics, the

electric hoist is a cornerstone tool—streamlining heavy-load movement while prioritizing safety and efficiency. From small-scale workshops to large manufacturing plants, choosing the right electric hoist depends on understanding its types, compliance standards, and real-world usability. This guide breaks down everything you need to know about electric hoists, including insights into industry-leading models (like those from

Henan Yangyumech Co., Ltd.) to help you make an informed decision.

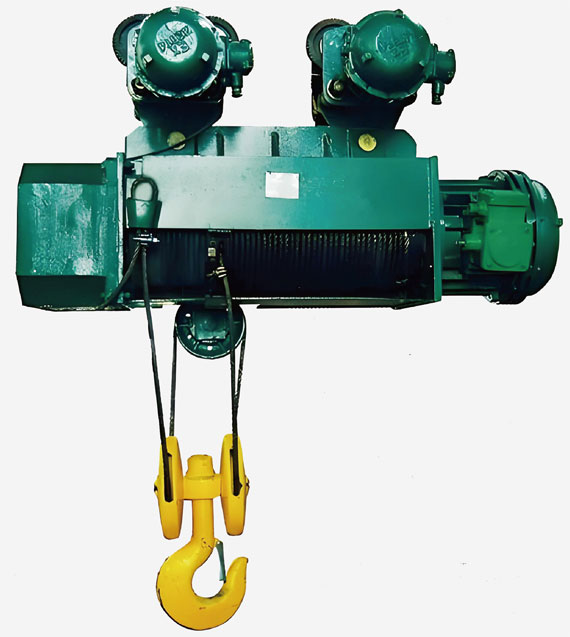

An electric hoist is a powered lifting device that uses an electric motor to lift, lower, and move heavy objects via a wire rope or chain. Unlike manual hoists (e.g., hand chain hoists), electric models eliminate manual labor, reduce fatigue, and enable precise control—making them ideal for repetitive or heavy-duty lifting tasks.

Key components of a standard electric hoist include:

- Electric motor: Powers the lifting mechanism (efficiency varies by standard, e.g., IE3 for European models).

- Lifting medium: Wire rope (for heavy loads) or chain (for precision and compact spaces).

- Brake system: Ensures load safety during power cuts or emergencies.

- Control unit: Pendant or remote controls for easy operation.

- Trolley (optional): Mounts the hoist on crane beams for horizontal movement.

Electric hoists are categorized by their lifting medium, design, and application. Below are the most popular types, including specialized models from Yangyumech— a trusted supplier with CE, ISO, and CNAS certifications (critical for global compliance).

A top choice for safety and precision, the European Standard Electric Hoist (offered by Yangyumech) adheres to strict EU norms (e.g., EN 13157, EN 60034). Its standout features include:

- Modular compact design: Integrates motor, reducer, and brake into a single unit (3-in-1 motor) for space-saving installation.

- Optimized force distribution: Enables fast, accurate load positioning—perfect for assembly lines or precision manufacturing.

- High efficiency: Uses IE3 premium motors to reduce energy consumption and carbon footprint.

Best for: EU-based factories, automotive plants, and businesses exporting to Europe (legal compliance with CE marking is mandatory).

Yangyumech’s Wire Rope Electric Hoist (CD/MD series) is a classic, versatile option for heavy loads. It comes in:

- Single-speed (CD model): For straightforward lifting tasks (e.g., warehouse pallet movement).

- Double-speed (MD model): For applications needing precision (e.g., loading fragile machinery).

Design highlights: Compatible with single-girder cranes, monorails, and I-beam structures—making it a staple in logistics centers and construction sites.

Load capacity: Ranges from small (1T) to heavy-duty (20T+), depending on the model.

Ideal for compact spaces and precise lifting, the Electric Chain Hoist (including Yangyumech’s European-style variant) offers:

- Easy installation: Works seamlessly with KBK standard track components (common in workshops and cleanrooms).

- Durable chains: Corrosion-resistant and wear-proof, suitable for indoor use (e.g., pharmaceutical or food processing plants).

Best for: Small to medium loads (1-10T), assembly lines, and areas where wire ropes might be too bulky.

A lightweight, portable option, the Micro Electric Hoist is designed for light-duty tasks. Yangyumech’s model shares similarities with the CD/MD series but is optimized for:

- Low load capacity: Typically 0.5-2T (ideal for small workshops or retail stockrooms).

- Easy maneuverability: Compact size for lifting small equipment or goods in tight spaces.

For horizontal movement, Yangyumech’s Electric Hoist & Trolley Set is a game-changer. The trolley mounts the hoist on heavy-duty bridge cranes or gantry cranes, offering:

- Simple structure: Lightweight yet sturdy, reducing maintenance needs.

- Dual functionality: Lifts vertically and moves horizontally—perfect for construction sites (e.g., lifting steel beams) or large factories.

While not electric, Yangyumech’s Hand Chain Hoist is worth noting for small-scale, short-distance tasks. Key specs:

- Load capacity: Up to 20T (usually ≤10T for daily use).

- Lifting height: Max 6m (suited for quick repairs or warehouse stock adjustments).

- Durability: High-quality alloy steel shell—sturdy, wear-resistant, and safe.

Compliance with global standards ensures your electric hoist is safe, legal, and reliable. Always verify these certifications (all offered by Yangyumech):

- CE Certification: Mandatory for EU markets—confirms adherence to health, safety, and environmental norms.

- ISO Certification: ISO 9001 (quality management) and ISO 14001 (environmental management) ensure consistent performance.

- CNAS Certification: Recognized globally, validating that the hoist meets international testing standards.

- European Norms (EN): For European Standard models, check EN 13157 (safety) and EN 60034 (motor efficiency).

Selecting an electric hoist depends on your specific needs—follow this guide to avoid costly mistakes:

- Rated load capacity: Match the hoist’s capacity to your heaviest load (never exceed it—risk of equipment failure). For example:

- Light tasks (0.5-2T): Micro Electric Hoist.

- Heavy loads (10-20T): Wire Rope Electric Hoist (CD/MD).

- Lifting height: Measure the vertical distance from the hoist’s mount to the lowest load position (e.g., 5m for warehouses, 30m for construction cranes).

- Space: Compact areas (e.g., workshops) need Electric Chain Hoists; large spaces (e.g., factories) benefit from hoists with trolleys.

- Conditions:

- Wet/dusty areas: Choose hoists with IP54+ ingress protection (prevents debris damage).

- EU/export markets: Prioritize European Standard Electric Hoists with CE marking.

- Speed: Single-speed (CD models) for simple tasks; double-speed (MD models) for precision (e.g., assembling electronics).

- Controls: Pendant controls (for close-range use) or remote controls (for safety in large/ hazardous areas).

Opt for suppliers like Henan Yangyumech Co., Ltd. that offer:

- Proven certifications (CE, ISO, CNAS).

- Diverse product lines (covers all key hoist types).

- After-sales support (maintenance, spare parts).

To extend your hoist’s lifespan and ensure safety, follow these practices:

- Regular inspections: Check brakes, wires/chains, and motors monthly (per EN standards for European models).

- Lubrication: Use manufacturer-recommended lubricants for chains and gears (prevents wear).

- Cleaning: Remove dust/debris from controls and trolley tracks to avoid jams.

- Operator training: Ensure staff know how to use the hoist safely (critical for compliance with EU’s EN 14987 standard).

- Genuine parts: Use Yangyumech’s original spare parts—non-compliant parts void certifications and risk accidents.

A: Wire rope hoists handle heavier loads (20T+) and are better for outdoor/rough conditions. Chain hoists are more compact, precise, and suited for indoor light-to-medium loads (1-10T).

A: Only if you need horizontal movement. Trolleys are essential for bridge/gantry cranes but unnecessary for fixed monorail setups.

A: Yes—their European Standard Electric Hoist and other models have CE certification, making them legal for EU use.

A: With proper maintenance, Yangyumech’s electric hoists last 10-15 years (European models often last longer due to IE3 motors and durable materials).

The right electric hoist boosts productivity, ensures safety, and keeps your operations compliant with global standards. Whether you need a precision European Standard model, a versatile CD/MD wire rope hoist, or a compact chain hoist, prioritize certified suppliers like Henan Yangyumech Co., Ltd.—their CE, ISO, and CNAS-marked products guarantee reliability.

For personalized recommendations (e.g., matching a hoist to your load capacity or industry), contact Yangyumech’s team to explore their full product line.

Post Views: 6