Home > Products > Gantry Crane > European-style double-girder gantry cranes

European-style double-girder gantry cranes

The core advantages of European-style double-girder gantry cranes lie in their “precision, efficiency, energy efficiency, and flexibility,” making them particularly suitable for small and medium-sized lifting applications with high requirements for space, precision, and environmental protection. Compared to traditional heavy-duty gantry cranes, they can maintain operational efficiency while reducing site constraints and operational costs, making them an ideal choice for lightweight lifting needs in modern industrial and logistics field.

Crane Capacity: 5ton-320ton

Working Class: A3, A4, A5, A6, A7

Description

1.The European-style double-girder gantry crane is a type of gantry crane.

2.The term “European-style” does not refer to a geographical region but rather denotes lightweight, modular, high-precision lifting equipment designed according to European standards.

3. Compared to traditional Chinese-style cranes, it focuses on a “compact structure + high-performance” design.

4.The main beam features a double-girder design (typically box-type beams or optimized H-section steel beams), while the legs form a gantry frame structure.

5. The crane moves along ground tracks via the main hoist travel mechanism, while the trolley (equipped with a hoisting mechanism) traverses the main beam horizontally, enabling three-dimensional cargo handling.

6.Its design complies with EU FEM standards or international ISO standards,focusing on material utilization, energy consumption control, and human-machine interaction, and is widely applicable to modernized operational scenarios such as automated production lines and smart warehouses.

Features

1.Using high-strength low-alloy steel (such as Q355B), the main beam, end beam, and other structures are optimized through finite element analysis. With the same lifting capacity, the self-weight is 15%-30% lighter than traditional cranes, resulting in lower load requirements for tracks and foundations and reduced infrastructure costs.

2.The lifting mechanism, trolley running mechanism, and other core components are highly integrated (e.g., compact motors and three-in-one reducers are used), reducing space requirements and making them particularly suitable for scenarios with limited factory height or span.

3.Standard variable frequency speed control system, with smooth adjustment of lifting, trolley, and crane running speeds (e.g., lifting speed 0.1-10 m/min), avoiding start-stop impact. This not only improves operational precision (positioning error can be controlled within ±5 mm) but also reduces energy consumption by more than 30%.

4.Some high-end models are equipped with PLC control systems and human-machine interfaces, supporting remote monitoring, fault diagnosis, and even connection to factory MES systems to achieve automated interconnection.

5.Key components (such as bearings, motors, and brakes) are mostly sourced from international brands (such as Siemens and SEW), with a service life of over 100,000 hours. Structural components undergo shot blasting rust removal and long-lasting anti-corrosion treatment, making them suitable for harsh environments with high dust levels and humidity.

6.Modular design facilitates component replacement. Routine maintenance only requires regular checks of the lubrication and braking systems, extending the maintenance cycle by 50% compared to traditional equipment.

7.Equipped with overload protection, limit position limiters (lifting height, operating range), emergency stop, anti-sway device (some models), etc., compliant with CE, ISO, and other safety certification standards, reducing operational risks.

Technical Data

| Capactit | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Lifting height | 7.5-35m | 14-40m | ||||||

| Work Duty | A3 | A4 | A5 | |||||

| Lifting Speed | 5/0.8m/min | 4/0.67m/min | 3/0.5m/min | 2/0.3m/min | ||||

| Hoist Trave Speed | 10-20m/min | 12-25m/min | 15-30m/min | |||||

| Crane Traveling Speed | 20-32m/min | 25-35m/min | 30-40m/min | |||||

| RAil | P18-P22 | P22-P24 | P24-P38 | P38-QU70 | QU70-QU80 | QU80-QU100 | QU100-QU120 | |

| span | 7.5-40m | |||||||

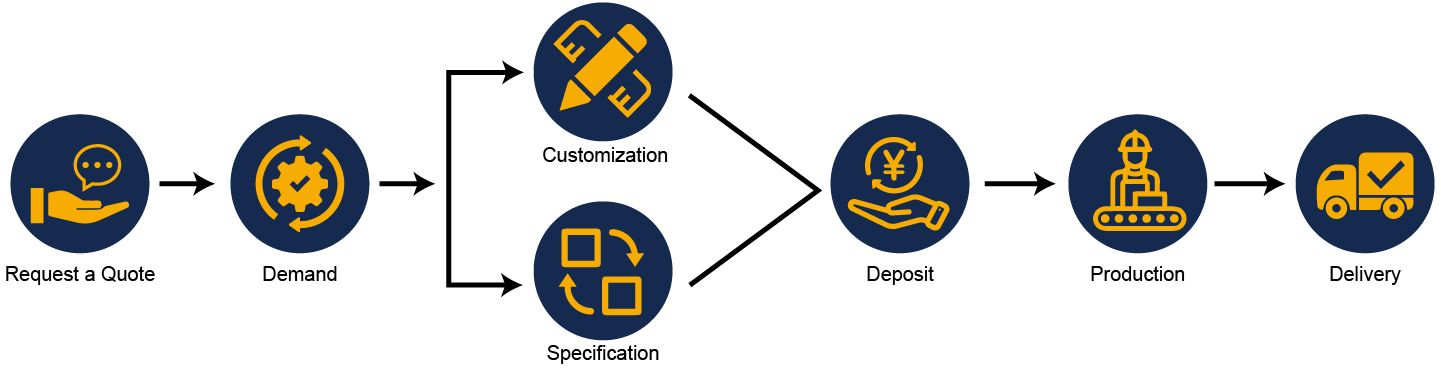

Purchasing process