Home > Products > Gantry Crane > Upper package lower fancy gantry crane

Upper package lower fancy gantry crane

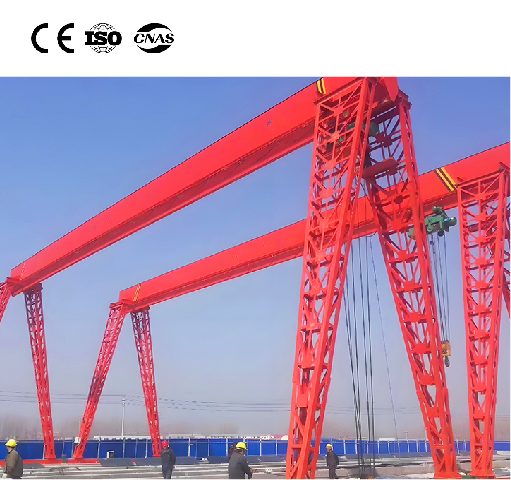

Upper “enclosed” structure: The main beam and trolley running area adopt a closed box-type structure (“enclosed”), formed by welding steel plates into a closed cross-section. This design enhances the main beam's torsional stiffness and overall stability, enabling it to withstand significant vertical loads and horizontal forces, making it suitable for high-precision operation of the hoisting mechanism. Additionally, the enclosed structure provides a more stable track foundation for trolley operation, reducing vibration and swaying, thereby ensuring safety during heavy-load or precision lifting operations.

Lower “lattice” structure: The legs and lower support sections adopt a lattice-type (“lattice”) design, formed by connecting structural steel (such as angle steel, channel steel) via bolts or welding to create a perforated truss structure. This structure significantly reduces the equipment's self-weight, minimizes pressure on the foundation, and offers excellent ventilation to reduce wind resistance, making it particularly suitable for outdoor, windy environments (such as ports and cargo yards).

Description

The upper box-type lower lattice-type gantry crane is an innovative lifting device that combines the advantages of two structural designs. Its design cleverly combines the characteristics of an upper closed box-type structure and a lower lattice-type truss structure, demonstrating unique performance and wide applicability in lifting operations.

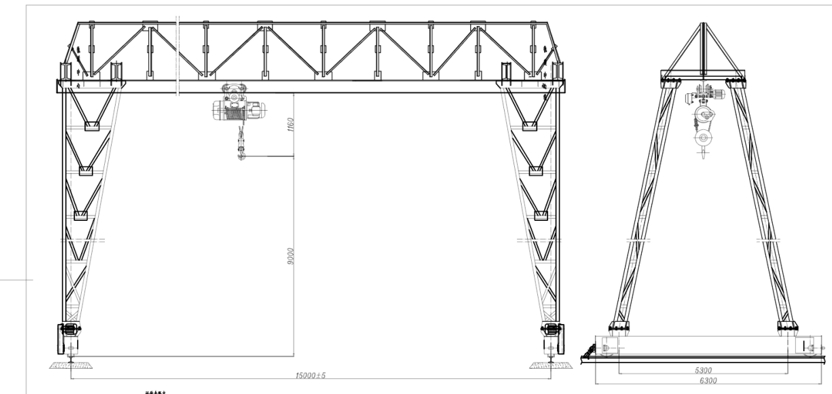

From a structural perspective, the upper part of the crane adopts a closed box-type main beam, which significantly enhances the equipment's torsional rigidity and overall stability, enabling it to stably carry medium to heavy loads of 5-50 tons and adapt to large-span operation scenarios of 15-40 meters, meeting the requirements for hoisting and transporting large cargo.

The lower section features a lattice-type trellis support leg design. The openwork structure not only effectively reduces the equipment's self-weight, lowers the pressure on the foundation, and reduces foundation construction costs, but also significantly reduces wind resistance, enabling stable operation in open, windy environments and enhancing the equipment's adaptability to complex climatic conditions.

Features

Upper closed box girder main beam:采用 box-type welded structure (primarily made of Q355B high-strength steel), with a rectangular closed cross-section. The torsional stiffness is over 40% higher than that of truss-type main beams, effectively distributing loads and reducing deflection deformation during long-span operations (e.g., for a 20-ton model, deflection ≤ L/1000 at a 32-meter span). ensuring stability during heavy-load (5-50t) lifting operations. Additionally, the enclosed structure protects internal walkways, cables, and transmission components from rain and dust, thereby extending the equipment's service life.

Lower lattice-type gantry crane legs: The legs are fabricated using angle steel or channel steel welded into a triangular lattice-type structure. The open design significantly reduces the equipment's self-weight (20%-30% lighter than fully enclosed gantry cranes), thereby decreasing the load on the foundation (reducing foundation bearing capacity requirements by 15%-20%) and saving on foundation construction costs. Additionally, the trellis structure has a low wind resistance coefficient (≤0.5), offering superior wind stability compared to fully enclosed models in open, windy environments such as ports and yards, and can withstand gusts of up to 8-10 on the Beaufort scale.

Wider operating range: Span coverage of 7.5–32 m (30% larger than single-girder gantry crane models), lifting height up to 6–24 m, with adjustable leg height to accommodate different site clearance requirements (e.g., factory eaves, container stacking areas). The smaller tonnage models (1-5 tons) emphasize flexible operation, while the larger tonnage models (10-20 tons) can meet the lifting requirements for long items (such as steel beams, precast panels) and heavy equipment.

Highly adaptable work level: Work levels are designed according to tonnage classification. Models ranging from 1 to 2 tons are classified as A3-A4 (light load, low frequency, such as sporadic loading and unloading in warehouses), while models above 3.5 tons are classified as A4-A5 (medium load, medium to high frequency, such as assembly line support in workshops and daily operations at ports). Some customized models can be upgraded to A6 (continuous operation) to meet the demands of different work conditions.

Precise speed control and smooth operation: The hoisting mechanism uses dual-speed or variable-frequency speed control (e.g., the 20t model has a hoisting speed of 0.4–4 m/min), ensuring smooth positioning at low speeds under heavy loads and efficient transportation under light loads; Trolley travel speed: 20–35 m/min; main crane travel speed: 30–50 m/min. The drive system is equipped with SEW or ABB motors, minimizing start/stop impact and achieving positioning accuracy of ±5 mm.

The upper-box, lower-truss gantry crane uses a “strong upper, light lower” structural combination that solves the problem of insufficient stability under heavy loads in truss-type main beams while overcoming the shortcomings of excessive self-weight and high wind resistance in all-box-type models. It is one of the optimal solutions for outdoor medium- to heavy-duty, large-span work scenarios in terms of strength, economy, and environmental adaptability.

Technical Data

| Capacity | 1t | 2t | 3.5t | 5t | 10t | 16t | 20t | |

| Span | 7.5-18m | 8-20m | 10-22m | 12-25m | 14-8m | 16-30m | 18-32m | |

| Lifting height | 6-12m | 6-14m | 8-16m | 8-18m | 10-20m | 12-24m | ||

| Work Duty | A3-A4 | A4 | A4-A5 | A5 | ||||

| Lifting speed | 8/0.8m/min | 6/0.6m/min | 5/0.5m/min | 4/0.4m/min | ||||

| Hoist Traveling Speed | 20-30m | 25-35m | ||||||

| Crane Traveling Sprrd | 10-30m | 15-35m | 20-40m | 25-45m | 30-50m | |||

| Rail | P22 | P22-P28 | P28-P38 | P38-QU70 | QU70-QU80 | QU80-QU100 | QU100-QU120 | |

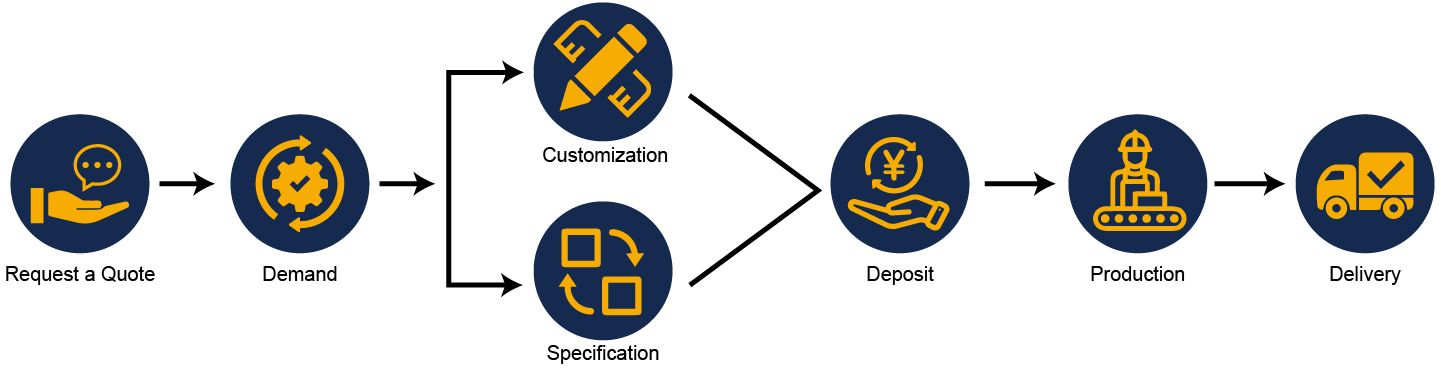

Purchasing process