In material handling and industrial operations, cantilever cranes provide exceptional flexibility and efficiency. Among the various types available, column-mounted (also known as freestanding) and wall-mounted cantilever cranes are two popular options. But when it comes to convenience, which one truly reigns supreme?

The answer, as is often the case in engineering, is: it depends entirely on your specific application, workspace layout, and operational needs. Column-mounted cranes offer unparalleled 360-degree rotation and independence from existing structures, while wall-mounted cranes excel in space efficiency for operations along walls. This article breaks down the key differences to help you determine which is most convenient for your facility.

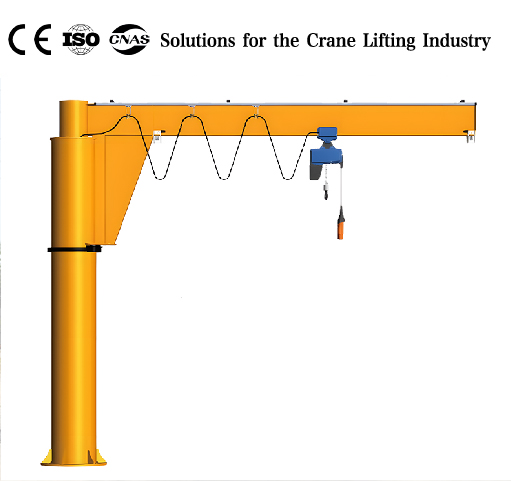

A column mounted cantilever crane features a vertical column anchored to a concrete foundation using anchor bolts. The jib arm rotates around this column, and an electric hoist moves along the arm to handle materials. This self-supporting structure operates independently of building supports.

A wall mounted cantilever crane is directly fixed to a sturdy load-bearing wall or structural column. Its jib arm typically has a limited rotation angle, usually 180 degrees or less, and it relies entirely on the wall’s structural integrity for support.

To determine which is more convenient, let’s compare them across several critical operational factors.

| Feature | Column Mounted Crane | Wall Mounted Crane |

|---|---|---|

| Foundation | Requires a dedicated concrete foundation with anchor bolts. | No floor foundation needed. |

| Structural Support | Self-supported; independent of building walls. | Depends entirely on wall strength; may require wall reinforcement. |

| Installation Complexity | Moderate; involves foundation work and assembly. | Simpler and faster if the wall is strong enough. |

| Engineering Costs | Primarily for foundation design. | May require significant engineering costs to verify wall can support the load. |

Convenience Verdict: The wall-mounted crane wins on installation speed and avoids floor excavation. However, if your wall requires reinforcement, the process can become complex and costly. The column-mounted crane has a more predictable, albeit physically intensive, installation process.

| Feature | Column Mounted Crane | Wall Mounted Crane |

|---|---|---|

| Floor Space Usage | Occupies precious floor space with its column and foundation. | Zero floor space occupation; ideal for cramped areas. |

| Work Envelope | Provides 360-degree rotation (can be specified as 180° or 270°), offering a large circular coverage area. | Limited rotation (typically ≤180°), covering a semi-circular area against the wall. |

| Interference | Can potentially interfere with other floor-based equipment or traffic. | Stays clear of floor obstructions, avoiding interference with larger overhead cranes. |

Convenience Verdict: For maximizing open floor space and servicing wall-adjacent areas, the wall-mounted crane is unbeatable. However, if you need coverage in the middle of a room or require full rotation, the column-mounted crane is far more convenient.

Both types are commonly available in standard capacities up to 2 tons, with larger models (3t, 5t) available for both, though wall-mounted versions may require more significant structural checks at higher capacities.

Column Mounted: Generally has high stability due to its robust foundation, which can support consistent performance at rated capacity.

Wall Mounted: Its capacity is limited by the strength of the existing wall structure. This might require a thorough inspection and potential reinforcement for heavier loads.

Convenience Verdict: The column-mounted crane offers more predictable and often less restricted load capacity, as it doesn’t rely on variable existing structures.

Column Mounted Crane: Once installed, it is fixed in place permanently. Its flexibility comes from its wide rotation, not mobility.

Wall Mounted Crane: Also fixed in place permanently. There is a third type, the wall-traveling jib crane, which runs on a track along a long wall, serving multiple workstations. This offers superior mobility for long, wall-based production lines.

Convenience Verdict: Both basic types are fixed. If mobility along a wall is a requirement, a wall-traveling jib crane would be the most convenient option, albeit at a higher installation complexity.

| Cost Factor | Column Mounted Crane | Wall Mounted Crane |

|---|---|---|

| Initial Equipment Cost | Similar to wall-mounted for comparable capacity. | Similar to column-mounted for comparable capacity. |

| Installation Cost | Higher due to concrete foundation work. | Lower, if the wall requires no reinforcement. |

| Additional Engineering | For foundation design. | Can be high to verify wall load-bearing capacity. |

| Long-Term Maintenance | Focus on mechanical parts and foundation integrity. | Focus on mechanical parts and wall connection integrity. |

Convenience Verdict: The wall-mounted crane can be more cost-effective if your walls are already sufficiently strong. However, unexpected costs for wall reinforcement can quickly negate this advantage. The column-mounted crane’s costs are more upfront and predictable.

| Factor | Column Mounted Crane | Wall Mounted Crane |

|---|---|---|

| Installation | Requires concrete foundation | Mounts on strong wall/column |

| Space Usage | Occupies floor space | Saves all floor space |

| Rotation | Up to 360° | Typically ≤ 180° |

| Ideal For | Open areas, multi-directional lifting | Against walls, compact spaces |

| Load Capacity | Limited by model design | Limited by wall strength |

| Mobility | Fixed position | Fixed position (unless wall-traveling) |

| Best Suited | Independent workstations, high frequency | Tight spaces, limited budgets, fixed wall-side lifting |

The most convenient choice is dictated by your specific facility’s layout and operational demands.

You need 360-degree rotation for maximum coverage in an open area.

Your lifting operations are not primarily against a wall.

Your existing walls are not strong enough to support a crane.

You have floor space available for a foundation and don’t mind it being occupied.

You require a predictable installation process based on a new foundation.

Your workstation is directly against a sturdy, load-bearing wall.

Maximizing open floor space is a critical priority.

A rotation of 180 degrees or less is sufficient for your operation.

You want a generally quicker installation process that avoids pouring a new foundation (assuming no wall reinforcement is needed).

Your budget for installation is potentially lower (again, assuming no wall reinforcement is needed).

There is no single winner in the debate between column-mounted and wall-mounted cantilever cranes. Convenience is application-dependent.

For spatial efficiency and servicing wall-adjacent areas, the wall-mounted crane is vastly more convenient.

For operational flexibility, full rotation, and independence from building structures, the column-mounted crane is the more convenient and capable choice.

The best way to decide is to consult with a qualified crane engineer. They can assess your facility’s structure, analyze your workflow needs, and recommend the optimal solution that balances convenience, performance, and cost for your specific operation.