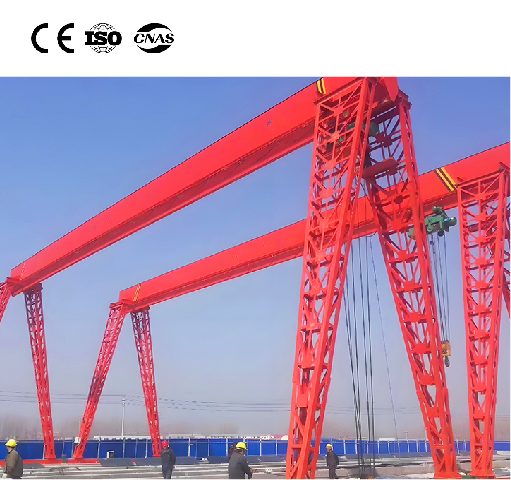

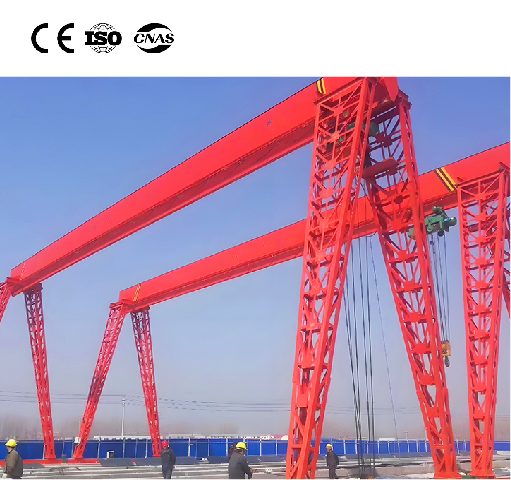

In the dynamic world of industrial lifting—where operations demand both heavy-duty load handling and precision for delicate tasks—the upper package lower fancy gantry crane has emerged as a versatile solution. Unlike traditional single-function gantry cranes, this specialized equipment combines two distinct lifting capabilities in one structure: a robust “upper package” for heavy loads and a flexible “lower fancy” system for precise, light-to-medium-duty operations. This guide dives into what makes this crane unique, its key features, applications, and why it’s becoming a top choice for businesses aiming to optimize workflow efficiency.

An upper package lower fancy gantry crane is a dual-purpose gantry crane designed with two independent lifting systems, tailored to handle diverse load requirements in the same workspace. Let’s break down its core definition and structure:

- Core Concept: The “upper package” refers to a heavy-duty main lifting mechanism (typically a hoist or trolley) mounted on the crane’s upper 主梁 (main girder), built for lifting large, heavy loads (often 5–50 tons). The “lower fancy” describes a secondary, more agile lifting system (such as a small hoist, jib crane, or telescopic arm) attached to the lower part of the crane’s structure—engineered for precise handling of lighter loads (0.5–5 tons) or tasks requiring fine positioning.

- Basic Structure: It retains the classic gantry crane framework (portal-shaped legs supporting a horizontal beam) but adds the dual-lifting upgrade. The upper system runs along the main girder for long-distance movement, while the lower system is often fixed or has a shorter travel range, focusing on localized precision.

- Material & Build: Most models use high-strength steel for the main structure (ensuring durability for heavy loads) and lightweight alloys for the lower system (enhancing its agility). Advanced models may also integrate anti-sway technology and corrosion-resistant coatings for use in harsh environments like outdoor yards or chemical plants.

Key Features That Make It Stand Out

The upper package lower fancy gantry crane solves a common pain point in industrial settings: the need to switch between heavy and precise lifting without investing in two separate cranes. Its standout features include:

1. Dual-Lifting Versatility

- Eliminates downtime from crane swapping: The upper package handles heavy tasks (e.g., lifting machine parts, steel coils) while the lower fancy tackles precision work (e.g., placing small components, loading delicate electronics) in the same area.

- Example: In an auto manufacturing plant, the upper system can lift a 30-ton car chassis onto an assembly line, while the lower system simultaneously positions 2-ton engine parts—cutting workflow time by 40% compared to using two single-function cranes.

2. Space-Saving Design

- Combines two cranes’ functionality into one structure, reducing floor space usage by 30–50%. This is critical for small to medium-sized workshops, warehouses, or factories where space is limited.

- Unlike tower cranes (which require vertical clearance) or mobile cranes (which need open ground), it operates within a fixed gantry frame, making it ideal for indoor/outdoor spaces with height or layout restrictions.

3. Precision + Power Balance

- Upper package: Equipped with high-torque motors and heavy-duty brakes, it ensures stable lifting of heavy loads with minimal sway (thanks to integrated anti-sway sensors).

- Lower fancy: Features variable-speed controls and 360° rotation (in jib-style designs), allowing operators to place light loads with millimeter-level accuracy—critical for industries like aerospace or electronics manufacturing.

4. Cost-Effective Operation

- Reduces upfront investment: Buying one dual-purpose crane costs 20–30% less than purchasing two separate cranes (heavy-duty + precision).

- Lowers long-term costs: Single structure = fewer maintenance parts, less energy consumption (vs. running two cranes), and reduced labor needs (one operator can manage both systems with training).

Top Applications Across Industries

The flexibility of the upper package lower fancy gantry crane makes it indispensable across multiple sectors. Below are its most common use cases:

1. Manufacturing & Assembly Lines

- Auto, aerospace, and machinery manufacturing: Lifts heavy frames (upper package) and installs small components (lower fancy) in one workflow. For example, a tractor factory uses the upper system to lift 40-ton tractor bodies and the lower system to attach 1-ton hydraulic parts.

- Electronics manufacturing: Handles heavy circuit board machines (upper) and places delicate microchips (lower) in cleanrooms—thanks to corrosion-resistant coatings and dust-proof lower system enclosures.

2. Warehousing & Logistics

- Distribution centers: Moves heavy pallets of goods (upper package) from trucks to storage racks, then uses the lower system to sort smaller packages into order bins.

- Cold storage facilities: The upper system lifts 10-ton frozen food containers, while the lower system transfers 1-ton boxes to packing stations—all while withstanding sub-zero temperatures (via insulated wiring and frost-resistant components).

3. Construction & Infrastructure

- Indoor construction (e.g., building malls, hospitals): Lifts heavy steel beams (upper) and positions lightweight drywall or electrical fixtures (lower) without disrupting other on-site work.

- Bridge maintenance: The upper package lifts 25-ton concrete repair materials, and the lower fancy uses a telescopic arm to reach narrow gaps for patching—eliminating the need for expensive mobile cranes.

4. Energy & Heavy Industry

- Renewable energy (solar/wind): Installs 30-ton wind turbine components (upper) and connects small electrical wiring (lower) on-site.

- Oil & gas: Handles heavy pipeline sections (upper) and tightens precision bolts (lower) in refineries—with explosion-proof lower systems for hazardous environments.

How to Choose the Right Upper Package Lower Fancy Gantry Crane

Selecting the best model depends on your specific lifting needs. Follow these steps to make an informed decision:

1. Assess Load Requirements

- Upper package capacity: Match it to your heaviest regular load (e.g., if you lift 25-ton machinery, choose a 30-ton upper system for safety).

- Lower fancy capacity: Consider your lightest, most precise tasks (e.g., 1-ton electronic parts need a 2-ton lower system for flexibility).

2. Evaluate Workspace Constraints

- Span (distance between gantry legs): Measure your workspace width—standard spans range from 5–20 meters, but custom spans are available for narrow/wide areas.

- Height: Check vertical clearance (floor to ceiling or outdoor overhead obstacles) to ensure the upper system can lift loads without obstruction.

3. Prioritize Safety & Compliance

- Look for safety features: Emergency stop buttons, overload sensors, anti-collision systems, and weatherproofing (for outdoor use).

- Ensure compliance: Choose models certified to ISO, OSHA, or CE standards (depending on your region) to avoid regulatory issues.

4. Consider Customization & After-Sales Support

- Custom options: Ask manufacturers about adding features like remote operation (for hard-to-reach areas), digital load monitoring, or specialized coatings (for harsh environments).

- After-sales service: Opt for suppliers that offer maintenance contracts, fast parts delivery, and operator training—downtime for a dual-purpose crane can disrupt two workflows at once.

Maintenance Tips to Maximize Lifespan

To keep your upper package lower fancy gantry crane running smoothly for 10–15 years, follow these maintenance best practices:

- Daily Checks: Inspect upper system brakes and lower system controls for wear; test anti-sway and emergency stop functions; clear debris from gantry rails.

- Monthly Servicing: Lubricate upper system gears and lower system joints; check electrical wiring for fraying; tighten loose bolts on the gantry frame.

- Quarterly Inspections: Hire technicians to calibrate load sensors (critical for both systems) and inspect the lower system’s rotation mechanism (if jib-style).

- Annual Overhauls: Replace worn parts (e.g., upper system hoist cables, lower system bearings); repaint rust-prone areas; update safety software (for smart models).

Future Trends for Upper Package Lower Fancy Gantry Cranes

As industries embrace automation and sustainability, this crane type is evolving to meet new demands:

- Smart Automation: Integration with IoT (Internet of Things) technology—real-time load monitoring, predictive maintenance alerts, and remote operation via mobile apps.

- Eco-Friendly Designs: Use of energy-efficient motors (reducing power consumption by 15–20%) and recyclable aluminum alloys for the lower system.

- Modular Upgrades: (detachable) lower systems that can be swapped for different tools (e.g., jib arm → telescopic fork) to adapt to changing tasks.

Conclusion

The upper package lower fancy gantry crane is more than just a lifting tool—it’s a strategic asset for businesses seeking to balance power, precision, and cost-efficiency. By combining two lifting functions in one space-saving design, it streamlines workflows, reduces costs, and adapts to diverse industry needs—from manufacturing to construction.

If you’re ready to upgrade your lifting operations, partner with a reputable manufacturer to customize an upper package lower fancy gantry crane that fits your load requirements, workspace, and safety standards. With the right model and maintenance, it will become the backbone of your efficient, future-ready operation.

Ready to learn more? Contact a crane expert today for a free consultation and quote!

Post Views: 6