In the modern industrial field that pursues efficiency and safety, a mature and reliable material handling technology has always been the cornerstone of the production process. The chain crane system, especially the chain electric hoist driven by electricity, is a core piece of equipment that perfectly combines mechanical power with control accuracy. It is not only a lifting tool for heavy objects, but also an intelligent solution that optimizes workflow, ensures operational safety, and unlocks the potential of three-dimensional space.

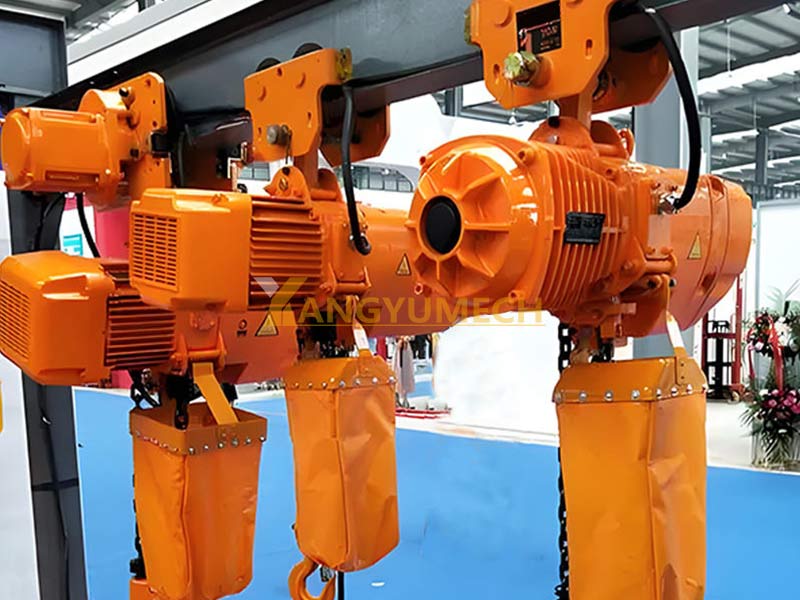

In essence, a chain crane system is a kind of lifting machinery that vertically lifts and lowers the load by driving a high-strength lifting chain. Its core power unit is usually a rugged motor, the energy it generates is adjusted by a precise gearbox, and finally converted into a smooth and controllable movement of the chain. The operator can intuitively control it through a hanging button station or a wireless remote control to achieve precise positioning of the load. The most distinctive feature of this system is its compact design and strong load capacity, which allows it to be easily integrated into existing factory structures or crane systems, creating maximum handling value in a limited space.

In order to adapt to various industrial scenarios from clean workshops to hazardous environments, chain cranes have developed a variety of special types to ensure that the most suitable tools are provided for each task.

Standard and high-speed models: Standard chain electric hoists have achieved a good balance between performance, reliability and cost, and are a common choice for general lifting tasks in workshops, warehouses and light industries. For automated production lines or assembly areas where every second counts, high-speed models can provide faster improvement speeds and significantly increase production beats.

Thin and variable speed models: In factories, ship compartments or low-rise workshops where space is highly restricted, thin chain hoists rely on their compact mechanical design to provide complete lifting capacity at the expense of very small head space. The variable speed model allows the operator to precisely control the lifting speed, which is essential for handling precision or vulnerable parts in aerospace or precision manufacturing, and can achieve fine positioning at the millimeter level.

Special safety models: Safety is always the primary consideration in industrial production. In places with flammable and explosive risks such as chemical industry, petroleum and natural gas, explosion-proof chain hoists are specially designed to eliminate the risk of electric sparks and overheating, and provide safety protection for operations in hazardous areas. In the food, beverage and pharmaceutical industries, food-safe chain gourds are made of stainless steel and have a smooth and easy-to-clean surface treatment to meet the most stringent hygiene standards and prevent the growth of bacteria.

The versatility of the chain crane system makes it the first choice in many key industries.

Manufacturing and automated production lines: In automobile manufacturing or mechanical assembly lines, chain electric hoists are widely used to quickly and accurately hoist large components, such as engines or axles, to designated stations. Its smooth operation and variable speed control capabilities ensure the quality and efficiency of precision assembly.

Warehousing and logistics center: In order to maximize the use of vertical storage space, chain electric hoists are often integrated in the lifting system of the warehouse to lift the goods to the shelf or remove them from the shelf. Its compact design is especially suitable for efficient operation in the limited space between the passage and the shelf.

Construction and equipment maintenance: On construction sites, it is used to safely transport building materials vertically. In the maintenance workshop, whether it is used independently or as a lifting unit of a jib crane, it is the right-hand man for equipment disassembly and component replacement, and can cover a flexible working radius.

In the face of diverse needs and complex environments, it is essential to choose an experienced and technically sound partner. As a manufacturer focused on lifting solutions, Yangyumech is committed to providing customers with chain crane products that exceed expectations. We know that reliability is the lifeline of equipment. Therefore, we use high-performance motors, durable gearboxes, and high-strength lifting chains to ensure that every equipment can cope with heavy industrial cycles.

Our advantage lies in combining excellent engineering quality with very competitive costs. We not only provide a series of standardized and efficient products, but we are also good at customized design and manufacturing according to the specific application scenarios of our customers-whether it is an explosion-proof chemical plant, a hygienic food workshop, or a production line that pursues extreme speed. In addition, our system design emphasizes integration with existing facilities to help you achieve a comprehensive upgrade of the material handling process with minimal retrofit costs.

We sincerely invite our customers to establish contact with us. No matter which industry you are in and what unique material handling challenges you face, Yangyumech’s professional team is willing to be your reliable consultant and partner. Let us discuss the needs together, design solutions, take the efficient and reliable chain crane system as the cornerstone, and work together to achieve a win-win situation of production efficiency and economic benefits.